Explosion Proof Isolators | 20A

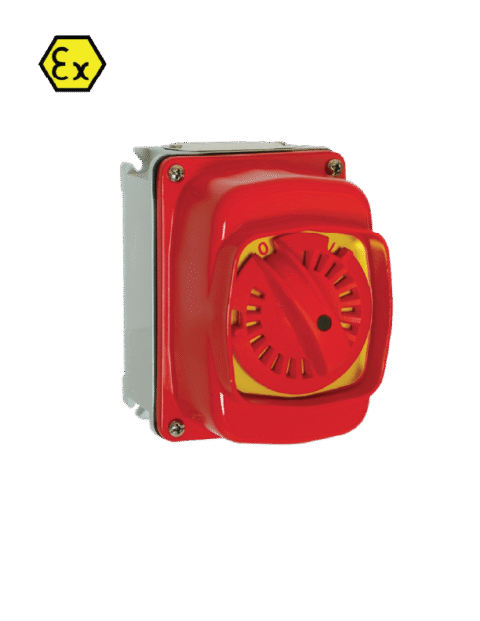

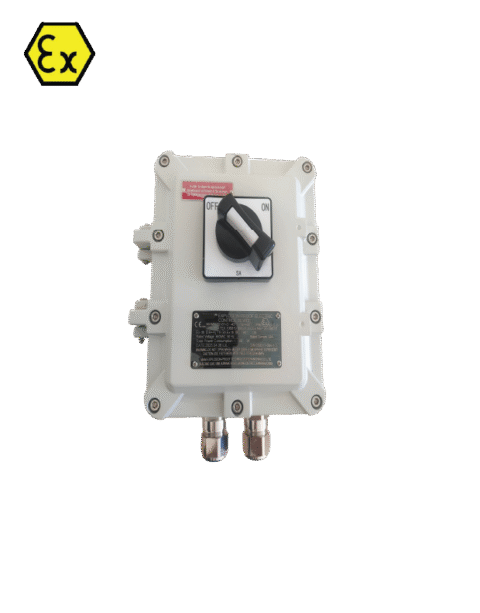

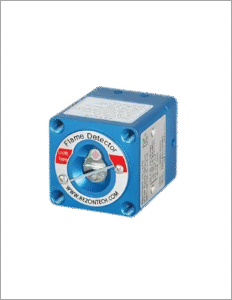

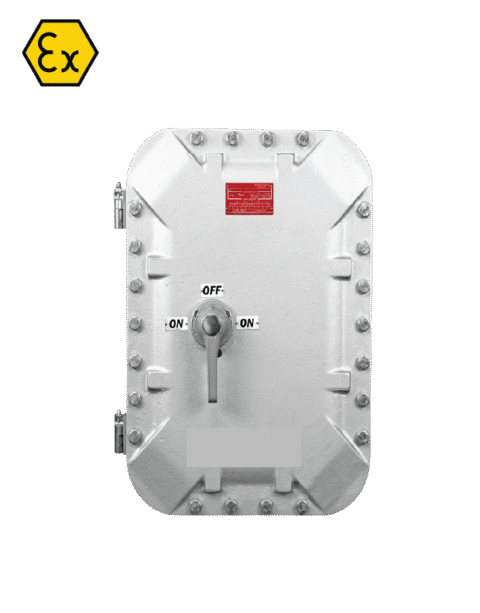

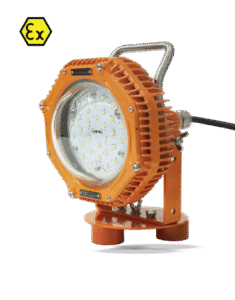

Safety is the top priority in oil and gas and chemical processing industries in the UAE. It is conducted before reading this article about explosion proof isolators on hazardous area. Such devices, like explosion proof isolators and atex isolator switches are significant in deterring any kind of sparks to typically experienced with Zones 1, 2, 21 and 22. They are certified safe for use under ATEX and IECEx standards ensuring the safety of both workers and equipment in explosive environments (gas or dust).

However, my goal is to logically perspective how these isolators/media are assist cells in UAE plants. I will explore their function in electrically isolating systems, ensuring they are compliant, and in selecting your precise equipment for your unique risks. That means this guide hits the technical notes and certifications but keeps it straightforward and jargon-free.

Key Takeaways

- Explosion proof isolators safeguard Zone 1 (gas) and Zone 21 (dust) areas from ignition sources.

- ATEX and IECEx certifications ensure equipment meets global safety benchmarks for hazardous zones.

- Proper selection of atex isolator switch models depends on current ratings and environmental conditions.

- Compliance with UAE regulations requires understanding Zone classifications and equipment ratings.

- Brands like CEAG offer certified solutions tailored to UAE industrial safety standards.

The Critical Role of Isolators in Hazardous Environments

Isolators act as a physical shield between electrical systems and dangerous zones. For instance:

- They block ignition sources in Zone 1 (gas) and Zone 21 (dust) areas

- Contain explosions internally if ignition happens (Ex d design)

- Employ flame-tight joints to manage heat and pressure release

Protection Principles in Hazardous Area Equipment

There are two primary protection methods:

- Ex d (flame proof isolator): Enclosures withstand internal explosions, redirecting energy safely

- Ex e (increased safety): Prevents ignition by limiting surface temperatures and spark generation

The choice between these methods hinges on the risk level of your workspace.

Understanding Hazardous Area Classifications: Zone 1, Zone 2, Zone 21 & Zone 22

Choosing the right explosion proof isolator or atex isolator switch hinges on precise workspace classification. Let’s delve into the zones outlined by global safety standards:

| Zone Type | Hazard Type | Risk Level | Example Applications |

|---|---|---|---|

| Zone 1 (Gas) | Gas | High risk | Near oil refinery pipelines |

| Zone 2 (Gas) | Gas | Moderate risk | Storage areas in chemical plants |

| Zone 21 (Dust) | Dust | High risk | Food processing machinery |

| Zone 22 (Dust) | Dust | Low risk | Warehouse storage zones |

In UAE facilities, such as Abu Dhabi’s refineries, engineers deploy explosion proof isolators in Zone 1 areas where gas leaks are a possibility. Conversely, atex isolator switches rated for Zone 22 are used in low-risk dust zones, like packaging lines. It’s crucial to align equipment with your zone classification to prevent dangerous mismatches.

ATEX & IECEx Certification Explained for UAE Applications

Understanding ATEX and IECEx certifications is crucial for hazardous area equipment compliance. These standards guarantee flame proof isolator systems are safe in explosive environments across UAE industries. Let’s explore their practical impact.

Information:

- Website: sensor-control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100