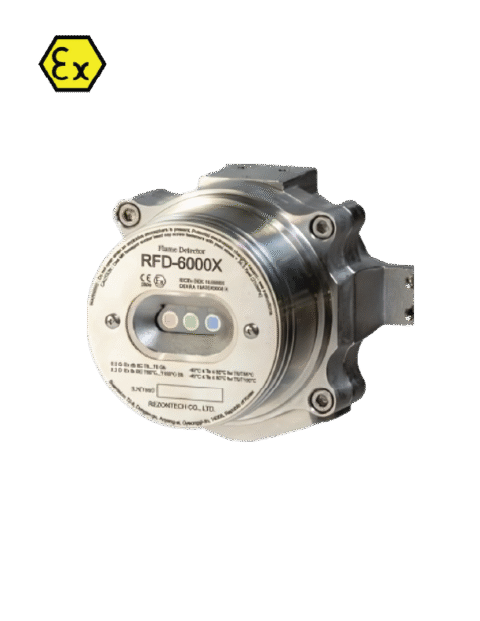

RFD-3000X IR3 Flame Detector – High-Performance Flame Detection for Hazardous Areas

The RFD-3000X is a robust, high-performance IR3 flame detector engineered for reliable fire detection in challenging industrial environments. Built with cutting-edge technology, this detector offers advanced performance in monitoring open flames using triple infrared (IR3) sensing. It is ideally suited for oil and gas, petrochemical, power generation, and other hazardous facilities where safety and timely flame detection are critical.

Key Features at a Glance

- Triple IR (IR3) Sensing Technology

- Long-Range Detection up to 197 feet (60 meters)

- Wide Field of View: 90° Horizontal, 90° Vertical

- Fast Response: Typically within 5 seconds

- Robust SUS 316 Enclosure

- Explosion-Proof with Global Certifications

- IP66/67 and NEMA Type 4X Rated Protection

Performance and Detection Capabilities

The RFD-3000X features IR3 flame detection, which uses three infrared sensors to detect the specific flicker and emission wavelengths of hydrocarbon flames. This triple-band approach helps eliminate false alarms from sunlight, hot objects, and other non-flame infrared sources. The detector achieves flame detection at distances up to 197 feet (60 meters), making it suitable for large open areas or zones with extended coverage needs.

With a field of view (FOV) of 90° horizontally and vertically, the RFD-3000X covers a wide area, reducing the number of detectors required in a facility. The detector responds quickly, typically within 5 seconds of flame presence, ensuring rapid hazard alerts.

Rugged Design and Environmental Resistance

Designed to operate reliably in extreme environments, the RFD-3000X is housed in a SUS 316 stainless steel enclosure, which offers excellent resistance to corrosion and harsh chemicals. It is engineered to function across a wide operating temperature range of -40°C to +75°C and can withstand humidity levels up to 95% relative humidity. These features make it ideal for outdoor use and in facilities where high moisture, dust, or aggressive chemicals are present.

The enclosure complies with IP66 and IP67 protection standards, ensuring the unit is completely dust-tight and protected against powerful water jets or immersion. Additionally, it meets the NEMA Type 4X rating, signifying resistance to corrosion and harsh weather, especially in marine and offshore environments.

Electrical Specifications

The RFD-3000X is designed for seamless integration into various industrial safety systems. It operates on a standard 24 VDC supply (compatible with a range between 18 VDC to 30 VDC) and consumes a maximum of 4.5W at 30VDC, offering energy efficiency for continuous use.

For signal output and monitoring, the unit supports both relay contact outputs and analog 4–20mA current outputs for key alarms such as fire detection, fault, and warning conditions. It also features RS-485 communication with a proprietary protocol, enabling real-time data transmission to centralized safety systems or control panels.

Two conduit entries are provided—1/2″ NPT or M20 x 1.5—offering installation flexibility in different global installations and wiring systems.

Global Certifications and Explosion-Proof Design

The RFD-3000X has been developed to meet stringent international safety and performance standards. It is certified by:

- FM3260

- CCC (China Compulsory Certificate)

- KFI (Korea Fire Institute)

The detector is explosion-proof, certified for use in hazardous zones, including:

- Class I, Division 1, Groups B, C, D

- Class II, Division 1, Groups E, F, G

- ATEX/IECEx/NEX (International and European Standards)

It holds the designation Ex d IIB + H2 T5, which confirms its suitability for environments with flammable gases, vapors, and hydrogen. This classification ensures the flame detector is safe for deployment in Zone 1 (Gas) and Zone 21 (Dust) environments, offering a broad scope of industrial applications.

Typical Applications

The RFD-3000X is ideal for environments where reliable flame detection is essential and where false alarms can result in costly operational disruptions. Common industries and use cases include:

- Oil & Gas Refineries

Detects hydrocarbon fires in processing units, tank farms, and pump stations. - Petrochemical Plants

Provides flame detection in environments with flammable liquids and gases. - Power Generation Facilities

Monitors turbine areas, diesel generator rooms, and fuel storage zones. - Offshore Platforms

Built to endure corrosive marine atmospheres and explosive gas atmospheres. - Chemical Manufacturing

Detects fires in volatile chemical processes and storage areas. - Waste Treatment Plants

Ideal for areas with flammable gases like methane from anaerobic digestion.

Advantages and Benefits

- Reliable Flame Detection

The IR3 sensor ensures high detection accuracy while filtering out non-flame IR sources, significantly reducing false alarms. - Long-Range and Wide Coverage

Up to 60 meters range and a 90°x90° field of view reduce the need for multiple detectors, lowering overall system costs. - Durability in Harsh Conditions

SUS 316 stainless steel housing and IP67 rating ensure long life even in extreme environmental conditions. - Flexible Output Options

Supports both relay contacts and analog signals, simplifying integration with new and legacy safety systems. - Certified Explosion Protection

Fully compliant with FM, ATEX, IECEx, and other global standards for use in hazardous areas.