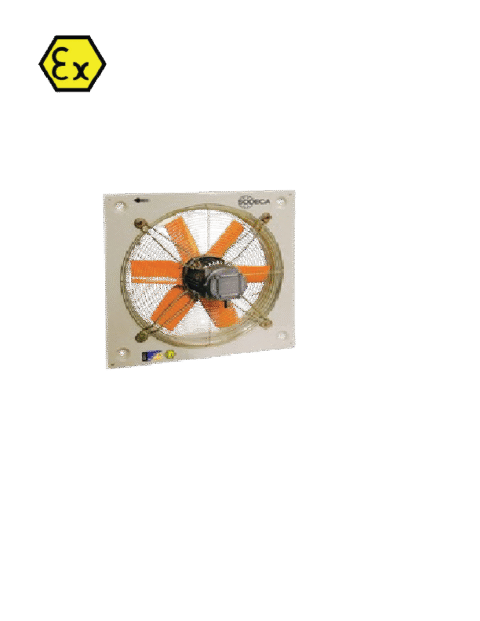

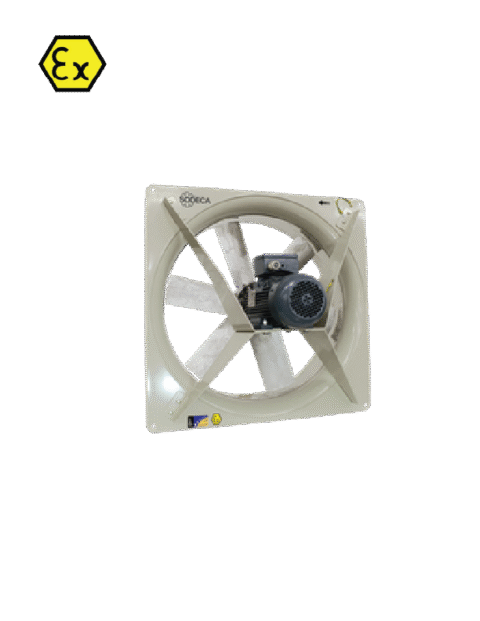

Wall Mounted Axial Fans with ATEX 2G/2D Certification and Ex db, Ex eb, or Ex tb Motors

Ventilation in hazardous environments requires specially engineered equipment that can withstand the risks of explosive gases and combustible dust. The wall mounted axial fans with ATEX 2G or 2D certification are designed for safe operation in such atmospheres, ensuring compliance, reliability, and efficiency. Built with robust materials and certified motors, these fans are ideal for industries such as oil and gas, chemical plants, hydrogen facilities, and dust-prone manufacturing areas.

Certified for Hazardous Areas

These wall mounted axial fans meet strict ATEX directives and can be supplied with different certified motor options:

- Ex db Flameproof Motor: II 2G Ex h IIB T4 Gb – Prevents ignition by containing explosions within the enclosure.

- Ex eb Increased Safety Motor: II 2G Ex h IIB T3 Gb – Reduces risks with enhanced design safety features.

- Ex tb Dust Ignition Proof Motor: II 2D Ex h IIIC T135 ºC Db – Ensures safe performance in explosive dust zones.

This flexibility ensures the right fan configuration is available for both gas (Zone 1, Zone 2) and dust (Zone 21, Zone 22) hazardous environments.

Fan Construction and Features

The design of these fans balances safety, strength, and performance for demanding industrial use:

- Cast Aluminium Impellers: Durable, lightweight, and resistant to sparks.

- Airflow Direction: From motor to impeller, ensuring smooth and efficient ventilation.

- Non-Sparking Cable Gland: Prevents ignition sources, standard on all models.

- Protection Grids: Installed on both sides for sizes 25 to 63; available as accessories for larger models.

- Steel Sheet Frame: Reinforced with aluminium band in the impeller area, compliant with EN 14986 standards.

This construction provides long-lasting safety while maintaining efficient airflow in hazardous areas.

Motor Options and Performance

The motor is the heart of the wall mounted axial fan, and multiple certified configurations are available:

- Class F Motors: High thermal endurance with insulation designed for long service life.

- Ball Bearings: Reduce friction and extend operational lifespan.

- Ex db / Ex eb / Ex tb Certified: Each motor type tailored for its respective hazard category.

- Voltage Options:

- Up to 4 kW: Three-phase 230/400 V, 50 Hz.

- Above 4 kW: Three-phase 400/690 V, 50 Hz.

- Operating Temperature: Safe use between -20 ºC and +40 ºC.

This combination makes the fans adaptable to a wide range of industrial environments and operational demands.

Protective Anti-Corrosive Finish

To ensure long-term durability, these fans are protected with an advanced surface treatment:

- Polyester Resin Paint: Applied and polymerized at 190 ºC for maximum durability.

- Iron-Free Coating: Prevents corrosion and ensures compatibility with explosive atmospheres.

- Nanotechnological Pretreatment: Phosphate-free degreasing improves adhesion and enhances surface resistance.

This protective finish makes the fans highly resistant to harsh industrial conditions, including chemical vapors, humidity, and dust exposure.

Optional Features and Customization

For industries with specialized requirements, the fans can be customized with a range of options:

- Motors with Built-in PTC Thermistors – Enhanced thermal protection.

- Special Windings – For non-standard voltages and frequencies.

- ATEX Dust Construction – Reinforced for heavy dust environments.

- Higher Protection Categories – For applications demanding more than the standard ATEX markings.

- Two-Speed Motors – Offering flexible airflow control.

- Single-Phase Flameproof Ex db Motors – Where three-phase power is not available.

These options give customers the ability to configure fans to their exact operational and safety needs.

Applications of Wall Mounted Explosion Proof Axial Fans

These fans are widely used in industries where safety and ventilation are critical:

- Oil & Gas Facilities – Offshore rigs, refineries, and storage sites.

- Chemical & Petrochemical Plants – Safe exhaust of flammable vapors.

- Hydrogen Production & Storage – Preventing gas accumulation and risk of explosion.

- Pharmaceutical & Food Industries – Ventilation in dust-laden environments.

- Paint Shops & Spray Booths – Handling solvent vapors safely.

- Battery Charging Stations – Ventilating hydrogen emissions.

- Milling & Grain Storage – Dust-proof ventilation solutions.

Their wall-mounted design makes them ideal for permanent installations where safe airflow is needed continuously.

Why Choose ATEX-Certified Wall Mounted Axial Fans?

- Safety Compliance – Meets ATEX 2G/2D standards with Ex db, Ex eb, or Ex tb motors.

- Durability – Anti-corrosive finish and robust construction withstand harsh industrial environments.

- Flexibility – Multiple motor options and customization features available.

- Efficiency – Optimized airflow direction ensures reliable ventilation.

- Versatility – Suitable for gas and dust explosive atmospheres across multiple industries.