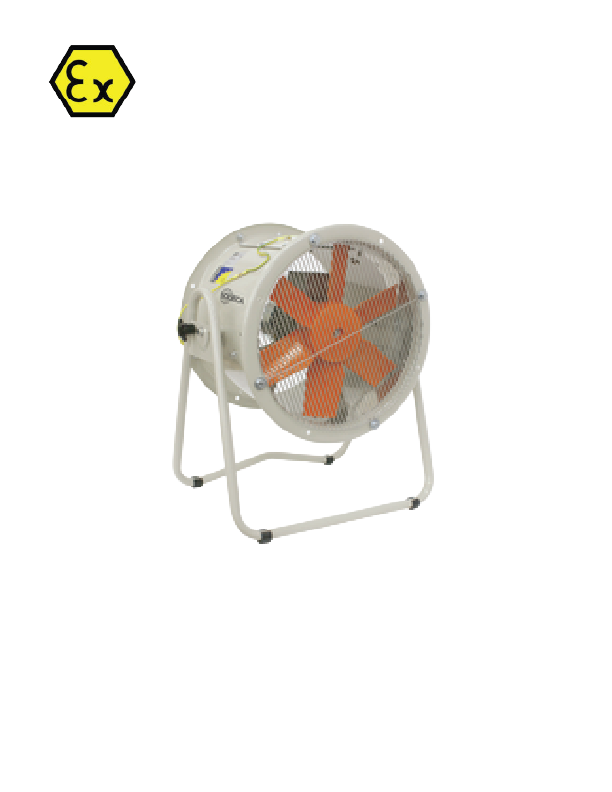

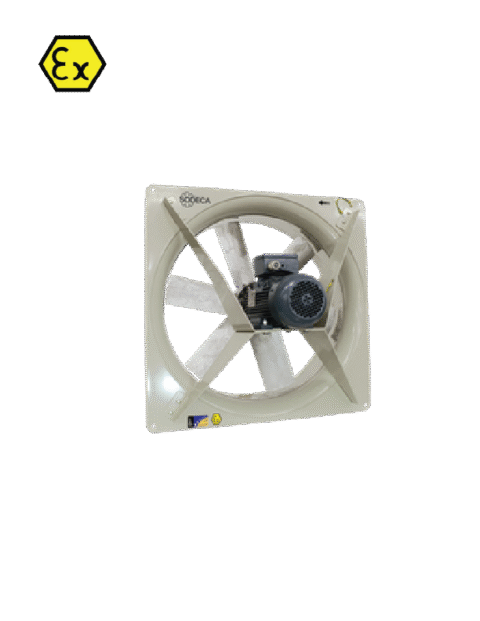

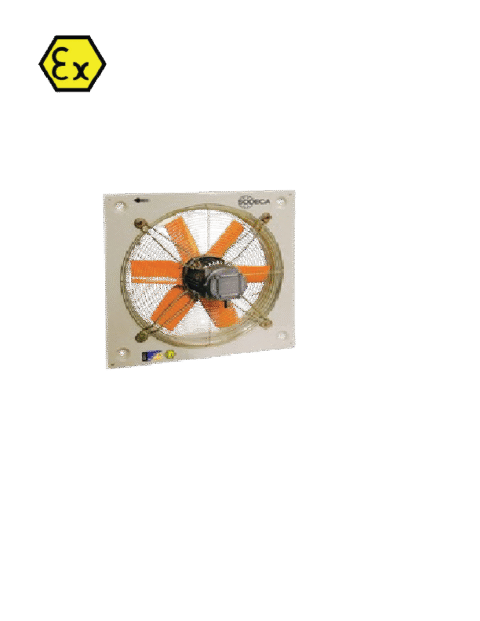

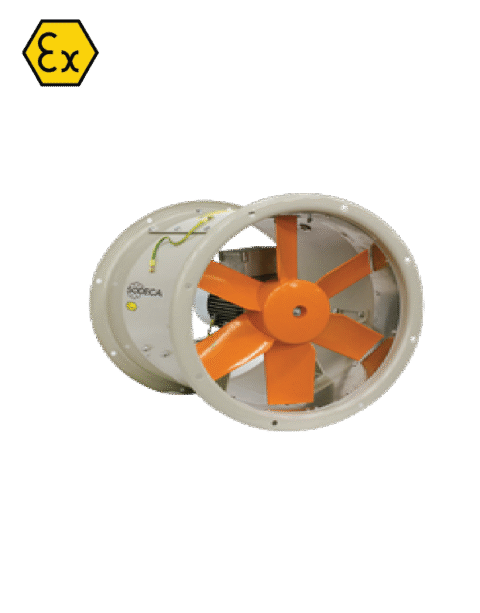

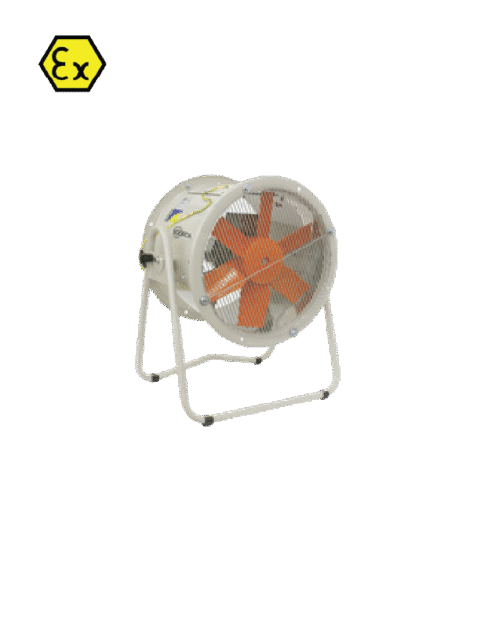

Tubular Mobile Fans with ATEX 2G/2D Certification and Ex db, Ex eb, or Ex tb Motors

In industries where explosive atmospheres are present, reliable ventilation systems are crucial for maintaining safety and operational efficiency. The tubular mobile fans with ATEX 2G or 2D certification are designed to deliver safe and efficient airflow in environments with explosive gases or combustible dust. Built with robust materials, advanced motor options, and strict compliance with international standards, these fans are ideal for hazardous industrial applications across oil and gas, chemicals, hydrogen, and dust-prone industries.

Certified for Hazardous Atmospheres

These tubular mobile fans are available with multiple ATEX-certified motor types, making them suitable for a wide range of hazardous environments:

- Flameproof Motor (Ex db): II 2G Ex h IIB T4 Gb – Designed to safely operate in explosive gas zones.

- Increased Safety Motor (Ex eb): II 2G Ex h IIB T3 Gb – Engineered for enhanced safety with lower operating temperatures.

- Dust Ignition Proof Motor (Ex tb): II 2D Ex h IIIC T135 ºC Db – Specially built for explosive dust atmospheres, preventing ignition even in the presence of high dust concentrations.

By offering different protection modes, these fans can be customized for specific hazardous zones, whether handling flammable gases, vapors, or dust particles.

Fan Design and Construction

The design of these tubular mobile fans ensures durability, compliance, and efficient performance:

- Tubular Casing: Constructed from high-quality sheet steel with an aluminium strip in the impeller zone, following EN 14986 standards for explosion-proof equipment.

- Cast Aluminium Impellers: Provide high airflow, lightweight construction, and long-lasting durability.

- Inspection Hatch: Allows easy maintenance and inspection, reducing downtime and ensuring safety compliance.

- Protection Grid: Located on both sides, designed according to UNE-EN ISO 12499, preventing accidental contact with the rotating impeller.

- Airflow Direction: Standardized to move air from the motor to the impeller for optimized cooling and airflow efficiency.

This rugged construction ensures reliability in demanding applications while maintaining compliance with strict explosion-proof standards.

Motor Options for Maximum Flexibility

The tubular mobile fans can be equipped with different ATEX-certified motor types, depending on operational needs:

- Ex db Flameproof Motors – For environments with explosive gases, fully enclosed to prevent ignition.

- Ex eb Increased Safety Motors – Lower temperature rise, extended safety margins for enhanced protection.

- Ex tb Dust Ignition Proof Motors – Prevent sparks and overheating, ensuring safe operation in dusty atmospheres.

Key Specifications:

- Motor Class: F (high thermal endurance).

- Bearings: High-quality ball bearings for long service life.

- Voltage Options:

- Three-phase 230/400 V, 50 Hz (up to 4 kW).

- Three-phase 400/690 V, 50 Hz (above 4 kW).

- Working Temperature: Suitable for environments ranging from -20 ºC to +40 ºC.

This wide operating range makes them adaptable for both indoor and outdoor hazardous area applications.

Durable Anti-Corrosive Finish

To withstand harsh environments, these fans are treated with an advanced anti-corrosive coating:

- Polyester Resin Coating: Polymerized at 190 ºC for durability.

- Iron-Free Composition: Prevents rust and corrosion, ideal for aggressive environments.

- Nanotechnological Treatment: Pre-degreased with a phosphate-free nanotech process, improving paint adhesion and surface protection.

This ensures long-lasting protection against chemical attack, humidity, and corrosive agents, making the fans highly reliable in offshore, petrochemical, and dusty applications.

Optional Features and Customization

These tubular mobile fans are highly versatile and can be tailored to specific industrial requirements:

- PTC Thermistors: Motors with built-in PTC (Positive Temperature Coefficient) thermistors for added thermal protection.

- Special Windings: Custom motor windings for different voltages and frequencies to match global standards.

- ATEX Construction for Dust: Enhanced dust protection for extreme powder handling environments.

- Higher Protection Categories: Fans can be built with protection levels greater than the standard marking for specialized needs.

- Two-Speed Motors: Available for applications requiring variable airflow rates.

- Single-Phase Ex db Motors: Option for flameproof single-phase motors in locations without three-phase supply.

This flexibility allows industries to deploy the fans in a wide range of environments, ensuring both safety and performance.

Applications of Tubular Mobile Explosion-Proof Fans

These fans are engineered for hazardous environments where explosive gases or combustible dusts may be present. Key applications include:

- Oil and Gas Facilities – Ventilation in refineries, offshore platforms, and storage terminals.

- Chemical and Petrochemical Plants – Handling flammable vapors and gases.

- Hydrogen Production and Storage – Safe ventilation in hydrogen-rich environments.

- Pharmaceutical Industry – Clean and safe handling of combustible dusts and solvents.

- Paint Shops and Spray Booths – Preventing ignition from paint fumes and vapors.

- Battery Charging Stations – Ventilation for hydrogen gas emissions.

- Milling, Grain, and Food Industries – Safe airflow in dust-prone zones.

Their mobility allows these fans to be positioned where ventilation is most needed, offering both flexibility and safety.