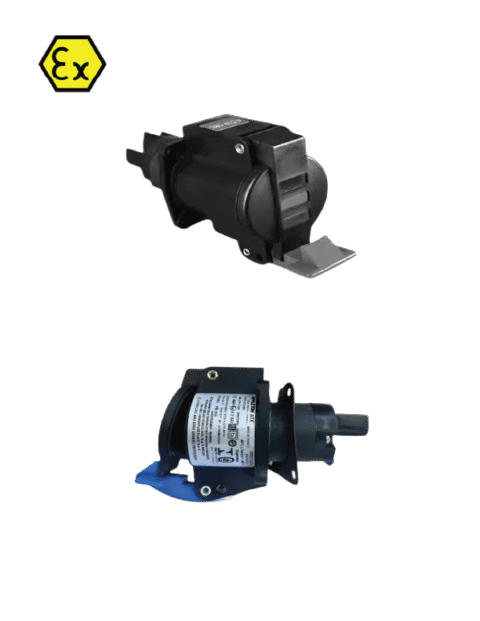

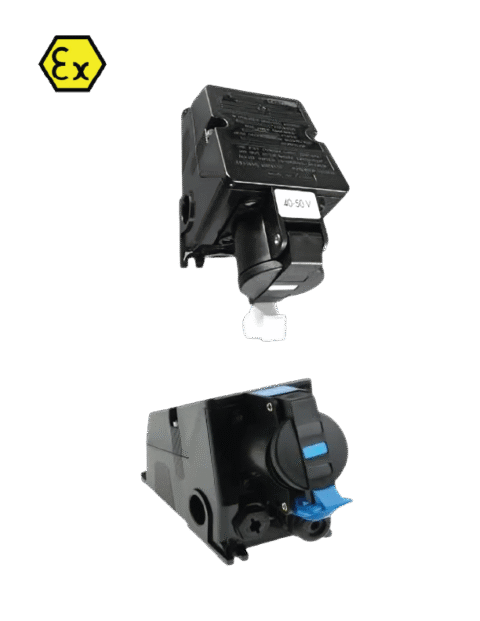

Appleton™ PN PRE316PY Explosion Proof Plug (PRE Series 16 A, 2P+E, 100–130 Vac)

Designed to deliver safe, reliable power in classified environments, the Appleton PRE316PY plug is part of the ATX™ PRE Series—engineered to meet the highest standards of explosion protection and rugged industrial performance. Certified to operate in hazardous gas and dust atmospheres, this plug is tailored for demanding applications across oil & gas, petrochemical, mining, and marine sites.

Certifications & Environmental Zones

- ATEX / IECEx Certified for use in Zone 1 & 2 (Gas) and Zone 21 & 22 (Dust) hazardous areas, rated II 2 GD Ex de IIC T6/T5 and Ex tD A21 IP66 per IEC/EN 60529.

- Sporting an IP66 rating and IK09/10 mechanical impact resistance, the PRE316PY is sealed against dust ingress and powerful water jets, and tough enough to withstand rough handling in heavy-duty environments.

- Built for extreme temperatures, it operates across a wide ambient range of ‑40 °C to +55 °C (‑4 °F to +131 °F), automatically adjusting its temperature class (T6 up to 40 °C, T5 up to 55 °C).

Technical Overview

- Rated Current: 16 A

- Voltage Range: 100–130 VAC (Low-Voltage range, color-coded Yellow per IEC scheme).

- Pole Configuration: 2P+E (Live, Neutral, and Earth).

- Frequency: 50/60 Hz

- Mounting Type: Cable-mount plug (polyamide) with built-in PG16 gland, accepts conductors up to 2.5 mm² and cable diameter Ø 6.5–14.5 mm

Safety & Functional Features

- Safe Disconnect Mechanism: Electrical separation occurs in two flameproof chambers—each phase disconnects automatically before exposure—minimizing arc risk and enhancing operator safety.

- Short-Circuit Rating: Designed for high fault currents up to 20 kA with a typical fault capacity of 10 kA, meeting stringent safety mandates.

- Keyed & Color-Coded: Each voltage version has a unique keyway and color marking to prevent misuse; PRE316PY is coded Yellow for easy identification and to prevent non-ATX plug insertion .

- IEC 309 Compatibility: While intended for hazardous locations, ATX plugs can safely connect to standard non-hazardous IEC 309 sockets where needed.

Material & Physical Attributes

- Housing: Robust polyamide body for the plug; wall and mobile socket options use high-impact polycarbonate or fiberglass-reinforced polyester as appropriate.

- Ingress & Impact Protection: Rated IP66 for complete dust sealing and strong water jet protection; IK09/10 ensures high mechanical durability.

- Compact Dimensions: Lightweight plug weighing ~0.2 kg (≈0.4 lb) and occupying ~0.6 dm³ (≈36 in³) volume—ideal for mobile or space‑constrained setups.

Typical Applications

The PRE316PY is widely adopted in industries requiring strict electrical safety in explosive atmospheres. Key uses include:

- Portable or fixed power connections for lighting, heaters, compressors, pumps, conveyors, and generators in petrochemical plants, oil refineries, offshore platforms, and gas compressor stations.

- Environments exposed to moisture, corrosive vapors, or dust—such as mining sites, food and grain processing, chemical plants, and outdoor installations.

- Flexible deployments where plugs may be frequently inserted, removed, or handled—its safe-disconnect design reduces risk on each cycle.

Highlighted Benefits

- Maximum Hazard Protection: Dual flameproof chamber design ensures safe phase disconnection before live exposure.

- Broad Environmental Compatibility: Operates reliably from –40 °C to +55 °C with high ingress and impact protection ratings.

- Voltage-Specific Safety Coding: IEC-standard color‑coding and unique keying eliminate cross-voltage misconnection.

- Robust Fault Tolerance: Short-circuit handling up to 20 kA (10 kA typical) ensures safety under fault conditions.

- Compact & User-Friendly: Lightweight, compact design with easy cable mounting and ergonomics that facilitate mobile use.

Certifications & Standards Compliance

- ATEX Directive 2014/34/EU – II 2 GD Ex de IIC (Gas) and Ex tD A21 (Dust) classification

- IECEx Certificate IECEx LCI 04.0014 – confirming global compliance

- IEC 60529 IP66 / IK09/10 – rated for severe environmental stress

- Temperature Class: T6 (Ta ≤ 40 °C), T5 (Ta ≤ 55 °C) in gas service; T68 °C dust surface limit

Installation & Ordering Guide

- Plug Only (PRE316PY): Yellow-coded, 16 A, 2P+E design for 100–130 VAC at 50/60 Hz.

- Mounting Options: Cable-mount is standard; wall-mount, flush-mount, and mobile socket variants available in the PRE Series model family.

- Cable Entry Specs: Integral PG16 gland supports cable diameters Ø 6.5–14.5 mm, with conductor size up to 2.5 mm²—suitable for typical portable power applications.

- Terminal Capacity: Designed for conductors up to 2.5 mm², with linked earth terminals for grounding continuity.

PRE Series Model Breakdown: PRE316PY Context

The PRE Series offers a structured range of products differentiated by voltage code and pole configuration:

- PRE316PY: 16 A, 2P+E, 100–130 VAC (Yellow) – the specific model discussed here

- Other variants include PRE316PB (200–250 VAC, Blue), PRE316RB (380–415 VAC, Red), and higher-current or multi-pole versions (3P, 3P+E, 3P+N+E) identified by color codes and catalog numbers.

Why Choose PRE316PY?

- Certified Safety in Harsh Environments: Trusted in explosion-risk zones across oil & gas, chemical, mining, grain, and marine sectors.

- Compact and Mobile-Ready: Lightweight and easy to handle in portable equipment without compromising industrial-grade robustness.

- Global Compatibility: Meets ATEX/IECEx and international design standards with consistent performance across geographies.

- User-Friendly Identification: Color-coding and keyed mating prevents common installation errors.

Contact Information:

![explosion proof plug and socket [aluminum]](https://sensor-control.ae/wp-content/uploads/2025/01/Artboard-1Explosion-Proof-Plug-and-Socket-480x621.png)