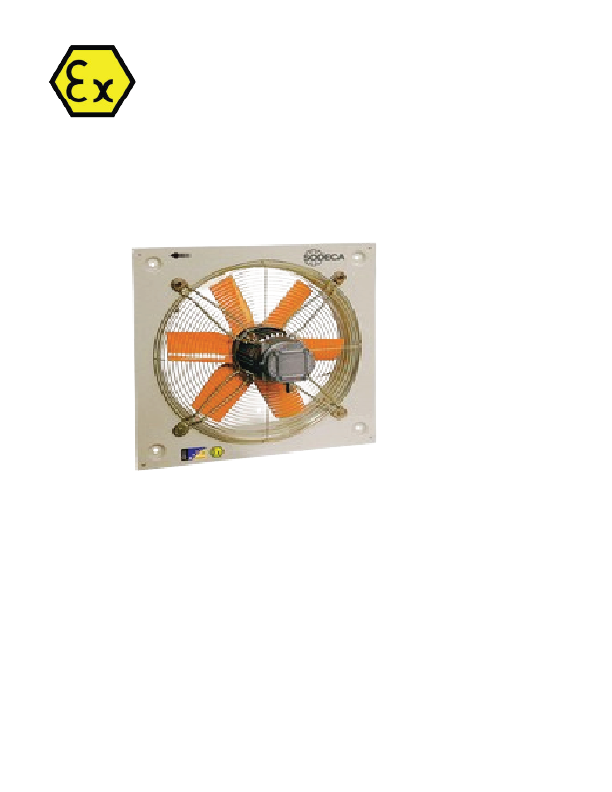

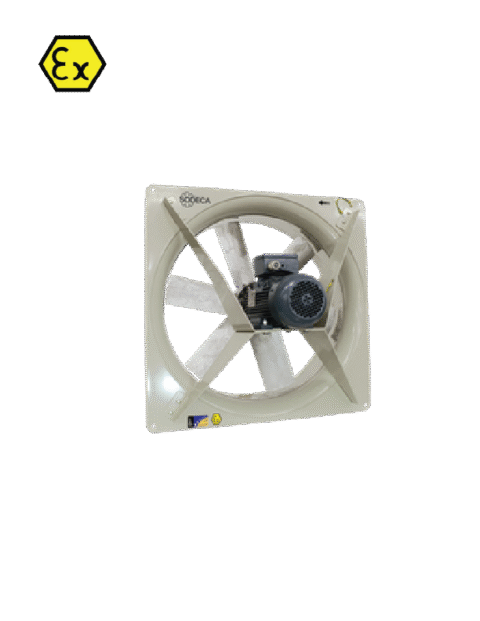

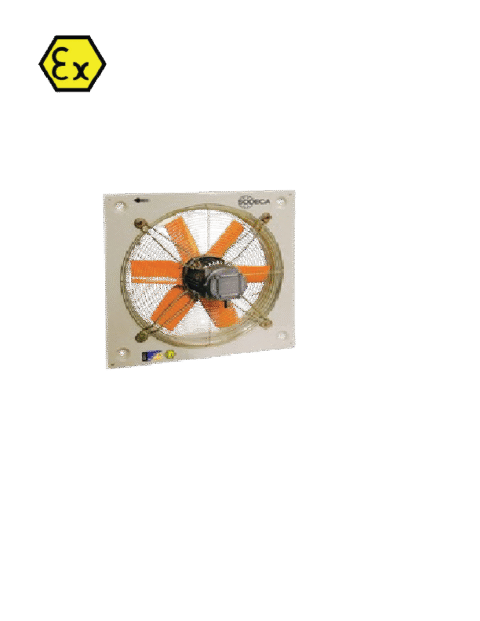

Flameproof Exhaust Fans with Square Frames and ATEX II 2G Certification for Hydrogen Applications

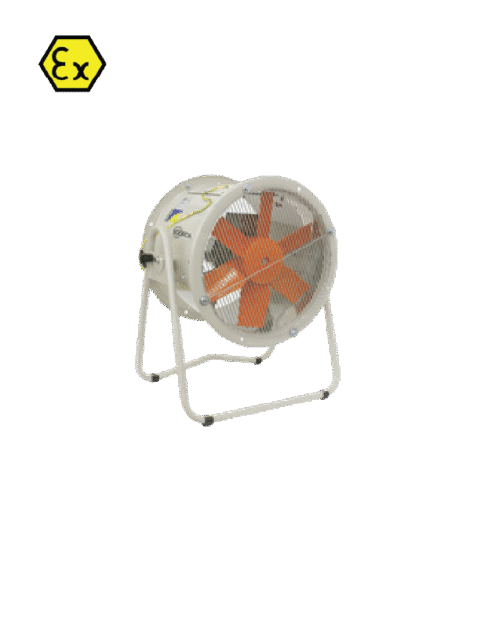

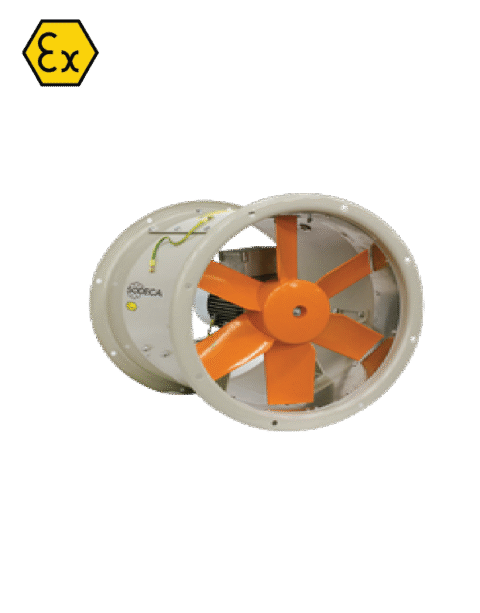

In industries where explosive atmospheres are a daily reality, ensuring reliable ventilation systems is critical for both safety and efficiency. One of the most robust solutions available for such demanding conditions is the ATEX-certified wall-mounted flameproof exhaust fan with square frame and Ex db flameproof motor, specially designed for hydrogen and other explosive gases. These fans combine advanced engineering, strict compliance with international standards, and durable construction to deliver exceptional performance in hazardous environments.

ATEX Certification and Safety Standards

The standout feature of these fans is their ATEX II 2G certification with an Ex db flameproof motor. This certification ensures that the fan is designed to safely operate in Zone 1 hazardous areas, where explosive atmospheres caused by gases, vapors, or mists may occur during normal operations.

Additionally, the fans carry the IIB+H2 T4 marking, which makes them suitable for use in hydrogen-rich environments, one of the most volatile and high-risk gases encountered in industrial processes. The T4 temperature class ensures that the surface temperature of the fan components remains below 135°C, preventing any chance of ignition.

By complying with EN 14986, UNE-EN ISO 12499, and other relevant international safety standards, these flameproof exhaust fans provide peace of mind to operators in chemical plants, refineries, laboratories, and hydrogen storage or processing facilities.

Fan Design and Construction

The fan section is engineered with safety, durability, and efficiency in mind.

-

Cast Aluminium Impellers: Lightweight yet strong impellers made from cast aluminium deliver efficient airflow while maintaining mechanical robustness.

-

Airflow Direction: Configured to move air from the motor to the impeller, ensuring optimum ventilation and cooling efficiency.

-

Flameproof Cable Gland: A flameproof cable gland is integrated to maintain the ATEX flameproof integrity and prevent sparks from escaping.

-

Steel Sheet Support Frame: The square frame is manufactured from high-quality steel sheet, with an aluminium band around the propeller area, fully compliant with EN 14986 for explosion safety.

-

Contact Protection Grid: To meet UNE-EN ISO 12499 standards, a protective grid is included to prevent accidental contact with the rotating impeller.

-

Standard Marking: Each unit is marked with the flameproof motor standard: II 2G Ex h IIB+H2 T4 Gb, highlighting its compliance with ATEX safety categories.

This robust design makes the flameproof exhaust fan both structurally strong and capable of long-term operation in challenging industrial environments.

Ex db Flameproof Motor

The motor powering the exhaust fan is a Class F motor designed to withstand demanding working conditions. Its key features include:

-

Ball Bearings: Provide reliable performance, low noise, and long service life.

-

IP55 Protection: Ensures resistance against dust ingress and water jets, extending durability in outdoor or humid conditions.

-

ATEX 2G Certification: Fully flameproof (Ex db) for safe use in Zone 1 environments.

-

Voltage Options: Available in both single-phase (230 V, 50 Hz) and three-phase configurations (230/400 V up to 4 kW, 400/690 V above 4 kW).

-

Temperature Range: Operates efficiently between -20 ºC to +40 ºC, covering a wide range of industrial applications.

This motor ensures that the flameproof exhaust fan can handle both standard and demanding conditions without compromising safety or efficiency.

Durable and Anti-Corrosive Finish

A major advantage of these flameproof exhaust fans is their anti-corrosive finish, which ensures long service life even in chemically aggressive or outdoor environments.

-

ATEX-Approved Paint: The fan surface is treated with polyester resin paint polymerized at 190 ºC.

-

Iron-Free Components: The coating is free from iron components, preventing rust formation.

-

Advanced Treatment: Surfaces are pre-treated with a phosphate-free nanotechnological process for enhanced adhesion and durability.

This finish ensures maximum resistance against corrosion, chemical attack, and wear, which is essential in hydrogen processing plants, offshore platforms, or chemical storage facilities.

Optional Features and Customization

To meet the diverse needs of industries, these flameproof exhaust fans can be customized on request:

-

Special Windings: Motors can be supplied with windings tailored for different voltages and frequencies to match global electrical standards.

-

Alternative ATEX Categories: Construction options for different ATEX categories and zones can be provided, depending on specific site requirements.

-

Two-Speed Motors: Fans can be equipped with dual-speed motors for applications requiring variable airflow rates.

These customization options make the fans adaptable to a wide range of industries and projects.

Applications in Hydrogen and Hazardous Environments

The combination of hydrogen compatibility, ATEX II 2G certification, and flameproof motor design makes these exhaust fans indispensable in industries where explosion risks are high. Typical applications include:

-

Hydrogen Production & Storage Plants

-

Chemical & Petrochemical Industries

-

Oil & Gas Refineries

-

Pharmaceutical Manufacturing

-

Laboratories with Flammable Vapors

-

Paint Shops and Spray Booths

-

Battery Charging Rooms

In all these scenarios, reliable ventilation is critical not just for operational efficiency but also for maintaining a safe working environment.