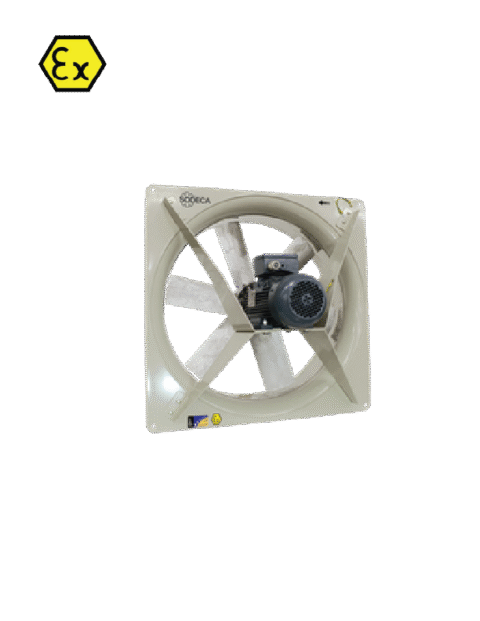

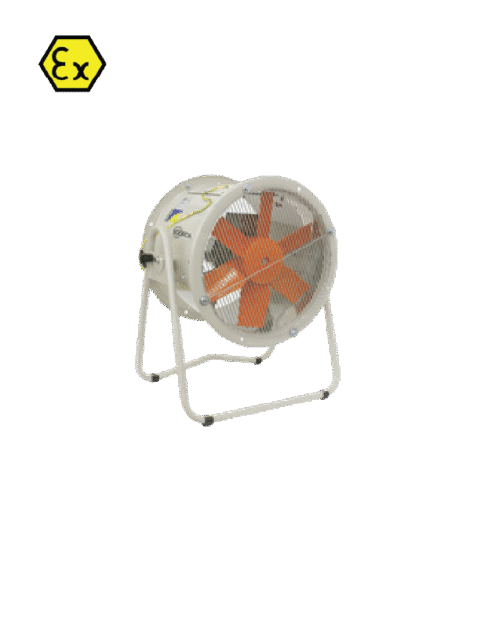

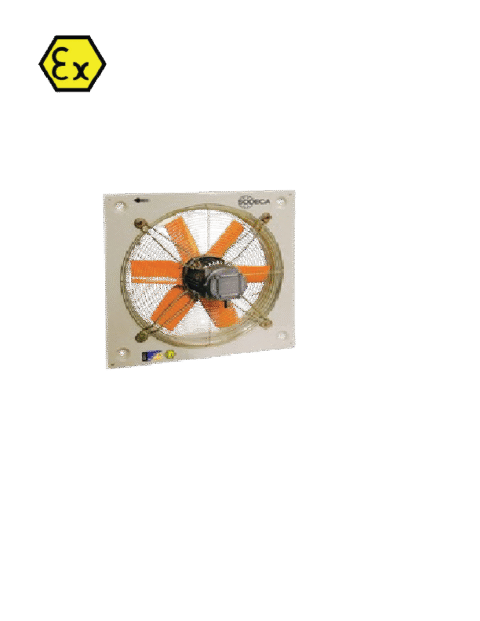

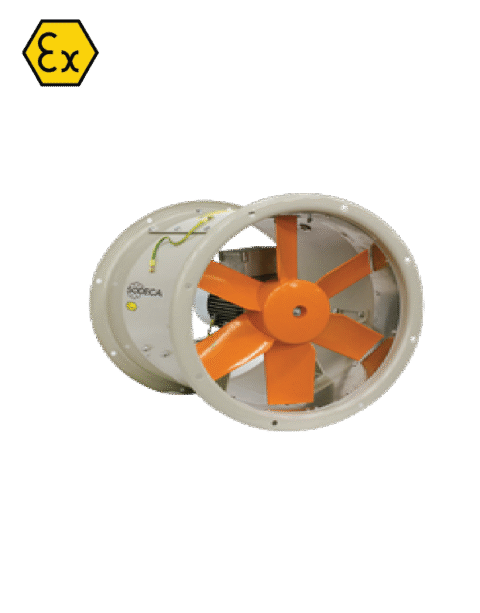

Extremely Robust Tubular Axial Fans with ATEX 2G/2D Certification and Ex db, Ex eb, or Ex tb Motors

In hazardous environments where safety is critical, ventilation systems must combine robust construction, international certification, and reliable performance. The tubular axial fans with ATEX 2G or 2D certification are specifically designed for explosive gas or dust atmospheres. With motor options including flameproof Ex db, increased safety Ex eb, and dust ignition proof Ex tb, these fans guarantee safe and efficient operation in industries such as oil and gas, petrochemicals, hydrogen production, and chemical plants.

ATEX-Certified for Hazardous Atmospheres

Safety compliance is at the core of these tubular axial fans. Depending on the application, they are available with multiple ATEX-certified motor protections:

- Ex db Flameproof Motors: II 2G Ex h IIB T4 Gb – contain internal explosions and prevent ignition of external gases.

- Ex eb Increased Safety Motors: II 2G Ex h IIB T3 Gb – reduce surface temperatures and increase safety margins.

- Ex tb Dust Ignition Proof Motors: II 2D Ex h IIIC T135 ºC Db – designed to prevent ignition in explosive dust-laden environments.

This wide range of certification makes these fans suitable for Zone 1, Zone 2 (gas) and Zone 21, Zone 22 (dust) installations.

Fan Construction and Design Features

The fans are engineered with durability and industrial safety in mind, ensuring consistent performance even in harsh conditions:

- Tubular Casing: Fabricated from high-quality sheet steel with an aluminium strip in the impeller zone, built in compliance with EN 14986 standards for explosion protection.

- Cast Aluminium Impellers: Lightweight, spark-resistant, and engineered for optimal airflow.

- Inspection Hatch: Allows easy maintenance access, reducing downtime.

- Airflow Direction: Standardized from motor to impeller, optimizing cooling and efficiency.

The robust tubular design ensures resistance against corrosion, mechanical stress, and industrial wear and tear, making the fans ideal for continuous operation in hazardous zones.

Motor Options and Performance

Each fan can be paired with motors designed for safety and adaptability:

- Ex db Flameproof Motors – prevent explosions from spreading outside the housing.

- Ex eb Increased Safety Motors – designed for cooler operation, minimizing ignition risks.

- Ex tb Dust Ignition Proof Motors – ideal for industries where explosive dust is present.

Motor Specifications:

- Class: F (high thermal resistance).

- Bearings: Durable ball bearings for extended service life.

- Power Range:

- Up to 4 kW: 230/400 V, 50 Hz three-phase.

- Above 4 kW: 400/690 V, 50 Hz three-phase.

- Operating Temperature: -20 ºC to +40 ºC, suitable for most industrial environments.

These features ensure that the fans perform reliably under demanding operating conditions.

Anti-Corrosive Protective Finish

To ensure long-term durability, the fans undergo a specialized surface treatment:

- Polyester Resin Coating: Polymerized at 190 ºC for maximum adhesion and resistance.

- Iron-Free Coating: Prevents corrosion and rust formation.

- Nanotechnological Pretreatment: Phosphate-free degreasing process enhances durability and coating effectiveness.

This advanced finish protects the fans against aggressive industrial atmospheres such as chemical vapors, humidity, and corrosive dusts.

Customization and Optional Features

To meet the diverse needs of industries, these fans are available with several optional configurations:

- Motors with Built-in PTC Thermistors – for advanced thermal monitoring and overload protection.

- Special Motor Windings – for non-standard voltages and global frequency requirements.

- Enhanced Dust Protection – ATEX builds designed specifically for heavy dust environments.

- Upgraded Protection Categories – beyond standard ATEX markings for specialized installations.

- Two-Speed Motors – provide variable airflow control for energy-efficient operation.

- Single-Phase Ex db Motors – for sites without three-phase power availability.

These options allow industries to customize fans to exact operational and safety requirements.

Applications of Tubular Axial Explosion-Proof Fans

The fans are widely used across multiple industries where explosion risks from gases or dusts are present:

- Oil & Gas Facilities – Offshore rigs, refineries, compressor stations, and terminals.

- Chemical & Petrochemical Plants – Handling volatile gases and vapors safely.

- Hydrogen Production & Storage – Mitigating risks in hydrogen-rich atmospheres.

- Pharmaceutical Industry – Ventilating solvent vapors and dust-prone environments.

- Paint Booths & Coating Plants – Preventing ignition of solvent-laden air.

- Battery Charging Rooms – Extracting hydrogen gas emissions safely.

- Milling, Grain, and Food Industries – Preventing explosions in dust-rich areas.

Their robust tubular design makes them suitable for heavy-duty, continuous operation, where both safety and reliability are essential.

Why Choose Extremely Robust Tubular Axial Fans?

- Certified Safety: ATEX 2G/2D compliant with Ex db, Ex eb, or Ex tb motors.

- Durable Design: Tubular steel casing and cast aluminium impellers for heavy-duty operation.

- Motor Versatility: Wide range of certified motor options for gas and dust hazards.

- Corrosion Resistance: Advanced anti-corrosive paint finish with nanotechnology pretreatment.

- Customizable Solutions: Available with PTC protection, special windings, two-speed motors, and single-phase Ex db options.