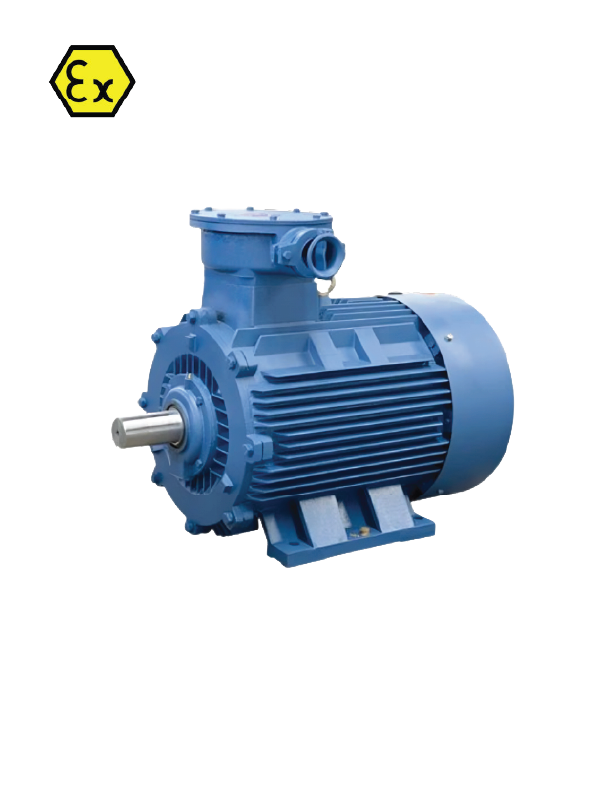

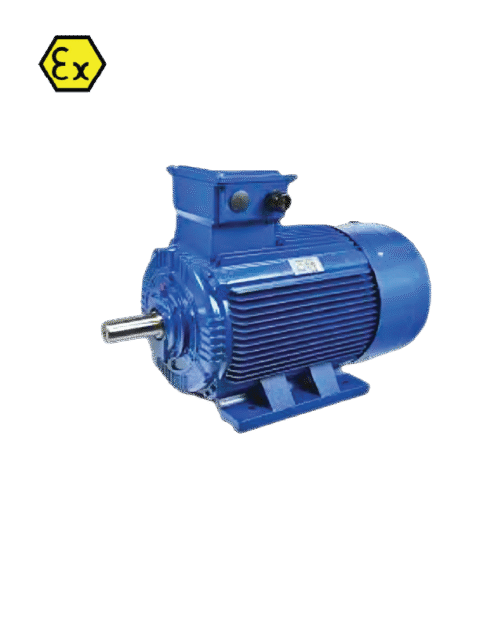

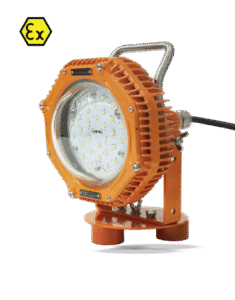

Explosion Proof Motor | 3DX 90L-2

The 3DX90L-2 Explosion Proof Motor is designed for use in hazardous environments where safety is paramount. Industries such as oil and gas, chemical processing, and manufacturing rely on this specialized electric motor to prevent accidents and ensure continuous operation.

Explosion proof motor is engineered to meet stringent safety standards, providing a reliable solution for challenging industrial applications. With its robust design and advanced safety features, it minimizes the risk of ignition in explosive atmospheres.

Key Takeaways

- Reliable operation in hazardous environments

- Compliance with stringent safety standards

- Robust design for challenging industrial applications

- Advanced safety features to minimize ignition risk

- Suitable for industries such as oil and gas, chemical processing, and manufacturing

Understanding the 3DX90L-2 Explosion Proof Motor Technology

Understanding the technology behind the 3DX90L-2 Explosion Proof Motor is essential for industries that require high safety standards. This motor is designed to operate in hazardous environments where the risk of explosion is high, making its technology and safety features paramount.

Technical Specifications and Performance Parameters

The 3DX90L-2 Explosion Proof Motor boasts impressive technical specifications that make it suitable for demanding industrial applications. Its performance parameters are designed to ensure optimal operation under various conditions.

Power Rating and Efficiency Metrics

The motor is available in various power ratings, including 2.2 kw and 35 kw options, catering to different industrial needs. Its efficiency metrics are optimized to reduce energy consumption while maintaining high performance. “The efficiency of explosion proof motors like the 3DX90L-2 is crucial for reducing operational costs and minimizing environmental impact,” as noted by industry experts.

“The efficiency of explosion-proof motors like the 3DX90L-2 is crucial for reducing operational costs and minimizing environmental impact.”

Construction Materials and Protective Features

The construction materials used in the 3DX90L-2 are selected for their durability and resistance to harsh environments. The motor’s protective features, including its explosion proof enclosure, ensure safe operation in hazardous conditions.

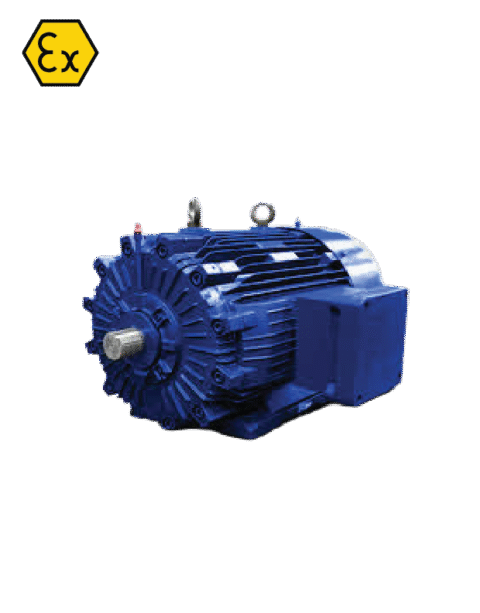

Comparison with Leading Brands like ABB and WEG Explosion Proof Motors

When compared to leading brands such as ABB and WEG, the 3DX90L-2 Explosion-Proof Motor stands out for its advanced technology and robust performance. While ABB and WEG offer high-quality explosion-proof motors, the 3DX90L-2 is competitive in terms of power rating, efficiency, and safety features.

- High efficiency metrics

- Robust construction materials

- Compliance with safety standards

In conclusion, the 3DX90L-2 Explosion-Proof Motor is a reliable choice for industries operating in hazardous environments, offering a blend of performance, safety, and efficiency.

Applications of Explosion Proof Motors in UAE Industrial Settings

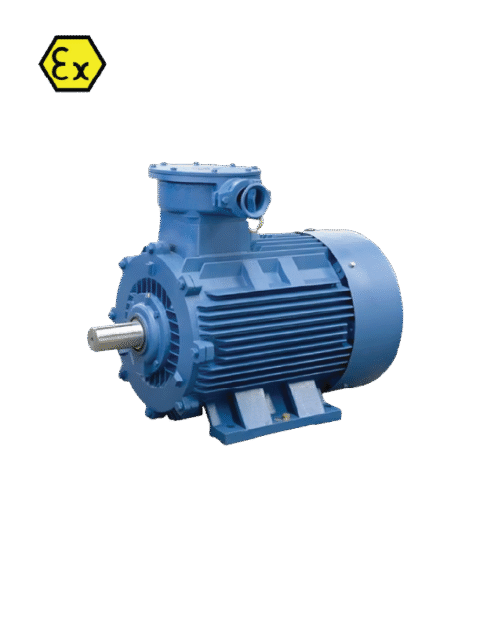

Explosion-proof motors are crucial in UAE’s industrial settings, including oil and gas, chemical processing, and manufacturing facilities. These motors are designed to prevent ignition sources in hazardous environments, ensuring operational safety and compliance with international standards.

Oil and Gas Sector Implementations

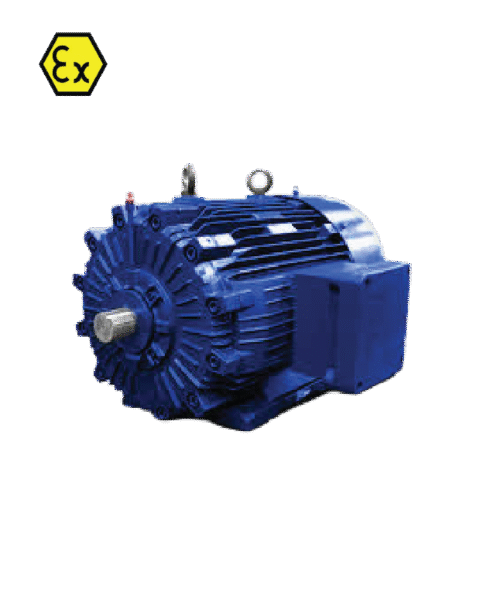

The oil and gas industry in the UAE relies heavily on explosion proof motors, particularly for applications requiring explosion proof blower motors. These motors are used in drilling operations, extraction processes, and in the transportation of oil and gas products.

For instance, in offshore drilling platforms, explosion-proof motors are essential for maintaining operational integrity and preventing accidents. The harsh environment demands equipment that can withstand extreme conditions while ensuring safety.

Chemical Processing and Manufacturing Facilities

In chemical processing and manufacturing facilities across the UAE, marathon explosion proof motors are utilized for their reliability and durability. These motors are critical in processes involving volatile substances, where the risk of explosion is high.

The use of explosion-proof motors in these facilities not only enhances safety but also ensures compliance with stringent regulatory requirements. Facilities using such motors demonstrate a commitment to operational safety and risk management.

Installation Requirements and Maintenance Protocols

Proper installation and maintenance of explosion-proof motors, such as 12 hp explosion proof motor and 13 hp explosion proof motor units, are critical for their effective operation. It is essential to follow manufacturer guidelines and adhere to local regulations.

Proper Installation Guidelines

Installation should be carried out by certified personnel who understand the specific requirements of explosion-proof equipment. This includes ensuring that all electrical connections are secure and that the motor is properly grounded.

- Ensure the motor is suitable for the specific hazardous area classification.

- Follow the manufacturer’s instructions for installation.

- Verify that all components are compatible and rated for the application’s requirements.

Maintenance Schedule and Best Practices

Regular maintenance is vital to ensure the longevity and reliability of explosion-proof motors. A scheduled maintenance program should include inspections, cleaning, and testing of the motor and its components.

- Conduct regular inspections to identify potential issues before they become major problems.

- Keep detailed records of maintenance activities.

- Use genuine parts for repairs and replacements.