Explosion Proof Isolators | 32A

Safe Electrical Isolation for Hazardous Areas in the UAE

Safety is the foremost priority in the oil & gas, petrochemical, chemical processing, and heavy industrial sectors across the UAE. Facilities operating in hazardous environments must strictly control ignition sources to prevent catastrophic incidents. In such conditions, Explosion Proof Isolators (32A) play a critical role by providing safe electrical isolation while maintaining compliance with international safety standards.

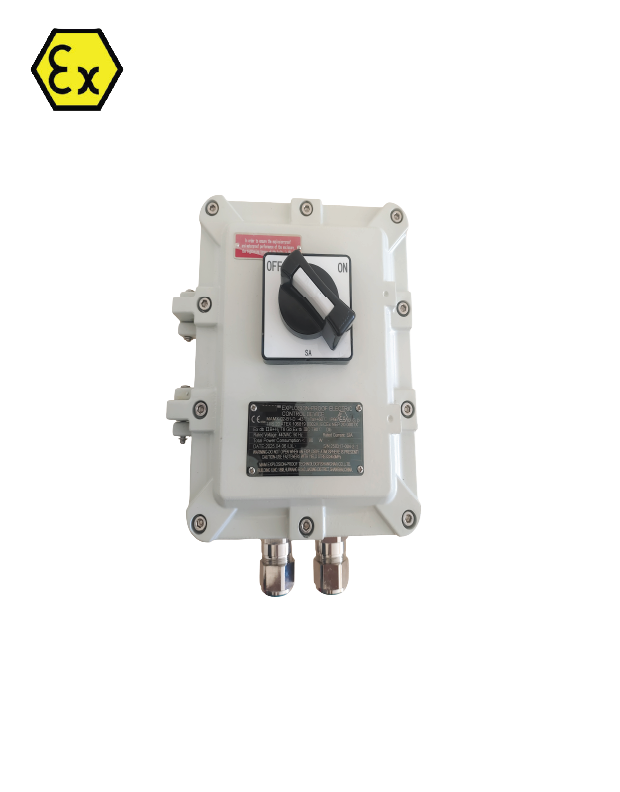

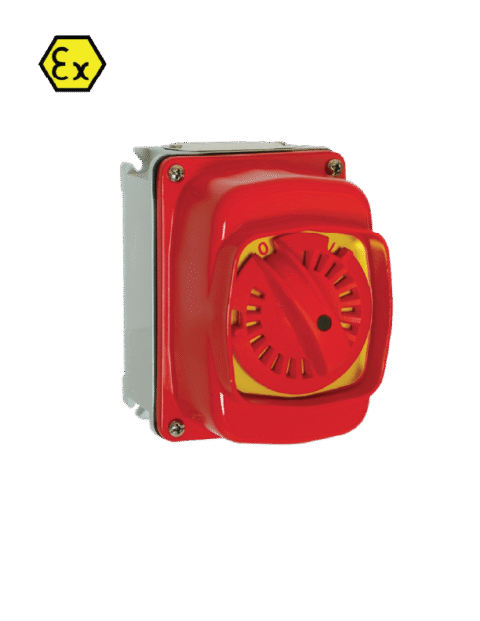

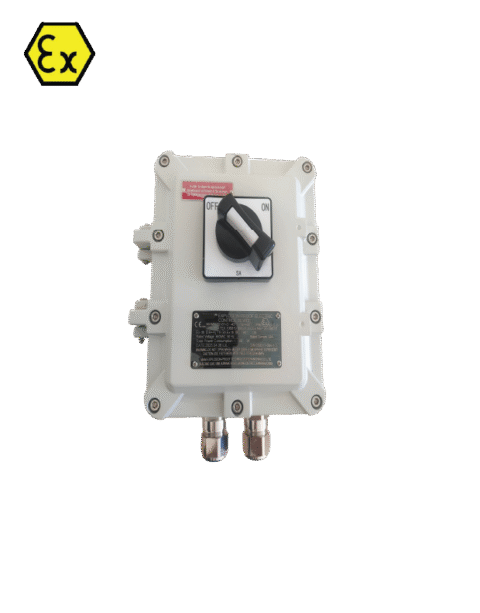

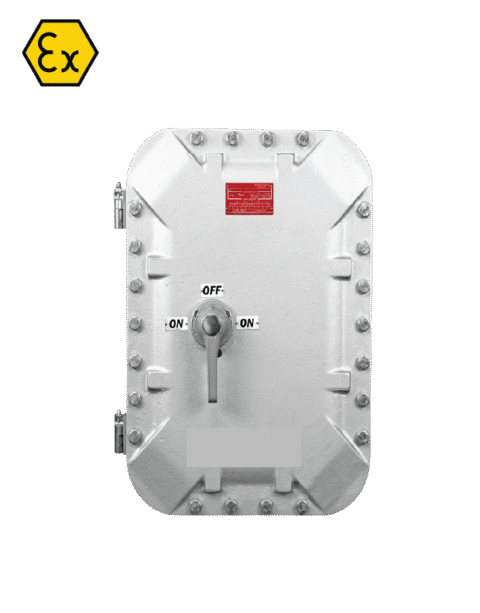

Designed for use in explosive gas and dust atmospheres, 32A explosion proof isolators and ATEX isolator switches are certified for Zone 1, Zone 2, Zone 21, and Zone 22 hazardous areas. These isolators ensure that electrical circuits can be safely disconnected during maintenance, emergencies, or routine operations without creating sparks, excessive heat, or ignition risks.

This article provides a clear and logical overview of how explosion proof isolators operate, why 32A ratings are essential for higher-load applications, and how UAE industries can select compliant, reliable equipment tailored to their operational risks.

Why Explosion Proof Isolators Are Essential in Hazardous Areas

Explosion proof isolators act as a critical safety barrier between live electrical systems and explosive atmospheres. In oil refineries, gas processing plants, offshore platforms, and chemical facilities, flammable gases, vapors, or combustible dust may be present during normal or abnormal operating conditions. A standard electrical switch can generate arcs or sparks, which can trigger an explosion.

A 32A explosion proof isolator is specifically engineered to eliminate this risk by enclosing all live components within a robust, certified housing. If an internal fault or ignition occurs, the enclosure contains the explosion and prevents flame propagation into the surrounding environment. This makes explosion proof isolators indispensable for ensuring plant safety and operational continuity in high-risk zones.

Understanding the 32A Rating and Its Importance

The 32-ampere (32A) current rating makes these isolators suitable for medium to high-power industrial loads. Compared to lower current isolators, 32A models are commonly used for:

- Pumps and compressors

- Process equipment and control panels

- Motors and auxiliary power circuits

- Industrial HVAC and ventilation systems

In UAE industrial environments, where equipment often operates continuously under harsh temperatures and demanding conditions, 32A explosion proof isolators provide the necessary electrical capacity without compromising safety or compliance.

Protection Concepts Used in Explosion Proof Isolators

Explosion proof isolators are designed using internationally recognized protection methods defined by ATEX and IECEx standards.

Ex d – Flameproof Protection

Ex d (flameproof) isolators are built with heavy-duty enclosures capable of withstanding an internal explosion. Key features include:

- High-strength cast aluminum or stainless steel housings

- Precision-machined flame paths

- Controlled pressure and temperature dissipation

This protection method is ideal for Zone 1 gas and Zone 21 dust environments, where explosive atmospheres are likely during normal operations.

Ex e – Increased Safety

Ex e (increased safety) isolators are designed to prevent ignition by eliminating arcs, sparks, and excessive surface temperatures. They feature enhanced insulation, reinforced terminals, and strict thermal limits. These are commonly used in Zone 2 and Zone 22 areas where explosive conditions occur infrequently.

Selecting the correct protection concept depends on the hazard level and zone classification of the installation area.

Hazardous Area Classifications Explained

Correct zone classification is essential when selecting a 32A explosion proof isolator. Hazardous areas are categorized based on the frequency and duration of explosive atmospheres.

| Zone | Hazard Type | Risk Level | Typical Applications |

|---|---|---|---|

| Zone 1 | Gas | High | Refineries, gas skids, pipeline areas |

| Zone 2 | Gas | Medium | Chemical storage and transfer zones |

| Zone 21 | Dust | High | Powder handling, food processing |

| Zone 22 | Dust | Low | Warehouses, packaging lines |

In UAE oil & gas facilities, Zone 1 isolators are commonly installed near valves, pumps, and processing units. Meanwhile, Zone 22-rated ATEX isolator switches are used in dust-prone but lower-risk environments such as bulk material handling areas.

ATEX and IECEx Certification for UAE Compliance

ATEX and IECEx certifications confirm that explosion proof isolators meet strict international safety requirements for hazardous environments. In the UAE, these certifications are often mandatory for projects governed by:

- ADNOC and ADNOC Group Companies

- EPC contractors and consultants

- Industrial safety authorities and audits

Certified 32A flameproof isolators ensure compliance with UAE regulations while offering confidence in long-term performance, durability, and reliability.

Environmental and Mechanical Considerations

UAE industrial environments expose electrical equipment to extreme heat, humidity, sand, and corrosive atmospheres. High-quality explosion proof isolators are designed to withstand:

- Ambient temperatures up to 55°C or higher

- High ingress protection (IP65 / IP66)

- Corrosion-resistant finishes

- Mechanical impact and vibration

These features ensure consistent operation even in offshore, desert, and coastal installations.

Applications of 32A Explosion Proof Isolators in the UAE

32A explosion proof isolators are widely used across multiple industries, including:

- Oil & gas production and refining

- Petrochemical and chemical processing plants

- LNG terminals and tank farms

- Power generation facilities

- Food, grain, and powder processing industries

Their ability to safely isolate power in hazardous zones makes them a vital component of modern industrial safety systems.

Trusted Explosion Proof Isolator Supplier in the UAE

Sensor Control LLC is a trusted supplier of ATEX and IECEx certified 32A explosion proof isolators in the UAE. We provide high-quality isolator switches suitable for Zone 1, Zone 2, Zone 21, and Zone 22 hazardous areas, with competitive pricing and expert technical support.

Contact Information

- Website: sensor-control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100

Reviews

There are no reviews yet.