Explosion Proof Exit Lights

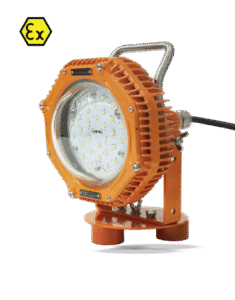

In hazardous environments such as oil refineries, chemical plants, offshore platforms, and grain processing facilities, safety is not optional — it is mandatory. One of the most crucial elements of any emergency safety system in these environments is the explosion proof exit light. These lights are specifically designed to withstand harsh conditions, prevent ignition of flammable atmospheres, and ensure safe egress during emergencies.

Explosion proof exit lights combine robust engineering, advanced illumination technology, and international certifications to provide reliable performance in the most demanding locations. By complying with global standards such as ATEX, IECEx, and UL844, they guarantee safety and peace of mind for both operators and facility managers.

Key Features of Explosion Proof Exit Lights

1. Explosion Proof Construction

The first and foremost feature of these exit lights is their rugged and explosion proof housing. Built from corrosion-resistant aluminum alloy or stainless steel, the enclosure is engineered to prevent internal sparks, flames, or hot gases from igniting hazardous gases, vapors, or dust in the surrounding atmosphere.

- Heavy-duty construction designed for Zone 1 & Zone 2 (gas) and Zone 21 & Zone 22 (dust) hazardous areas.

- Precision-sealed joints to eliminate the risk of gas penetration.

- High mechanical strength to withstand shocks, vibrations, and heavy-duty industrial use.

2. International Certifications

Explosion proof exit lights are tested and certified according to international safety regulations for hazardous locations. This makes them suitable for global projects and ensures compliance with stringent industry standards.

- ATEX (Europe) and IECEx (International) certification.

- UL844 and cULus approvals for Class I, Division 1 & 2, and Class II, Division 1 & 2 locations.

- Compliance with IP66 or higher ingress protection ensures resistance to dust, water, and harsh weather conditions.

These certifications guarantee that the lights can be safely used in environments with flammable gases, vapors, or combustible dusts.

3. Advanced Illumination

Explosion proof exit lights use high-efficiency LED technology to provide clear and reliable visibility under all conditions. LEDs are not only energy-efficient but also deliver long operational lifespans, minimizing maintenance requirements.

- Bright and uniform illumination ensures exit signs are visible in smoke, darkness, or long-distance conditions.

- Energy-efficient design reduces power consumption.

- LEDs have an average lifespan of 50,000+ hours, offering long-term reliability.

4. Durability and Reliability

Industrial hazardous areas are often exposed to salt water, chemicals, extreme temperatures, and abrasive dusts. Explosion proof exit lights are built to endure these tough conditions without compromising performance.

- Impact-resistant housings to withstand mechanical damage.

- Weatherproof and corrosion-resistant finishes.

- Designed to operate reliably across a wide ambient temperature range, typically from -40°C to +55°C.

- Long-lasting materials that ensure dependable service life, even in offshore and marine conditions.

5. Power Supply and Emergency Backup

Explosion proof exit lights are designed with multiple power supply options to ensure functionality during normal operation and emergency conditions.

- AC-powered models for standard industrial use.

- Integrated backup battery systems that automatically activate during a power outage, providing uninterrupted illumination.

- Rechargeable, maintenance-free batteries with extended operating duration.

This feature is vital in high-risk facilities where safe evacuation during power loss can save lives.

6. Flexible Mounting Options

Every facility has unique requirements, and explosion proof exit lights are designed with versatile mounting configurations for maximum adaptability.

- Wall-mounted for standard hallway and passageway installations.

- Ceiling-mounted for overhead visibility.

- Pendant mounting for areas requiring suspended lighting solutions.

This flexibility makes them suitable for both indoor and outdoor hazardous locations.

Applications of Explosion Proof Exit Lights

Explosion proof exit lights are essential safety devices across a wide range of industries, including:

- Oil and Gas Refineries – Providing safe evacuation routes during emergencies such as gas leaks or fires.

- Chemical Plants – Ensuring visibility in environments with highly volatile chemicals.

- Grain Silos and Mills – Preventing ignition risks from combustible dusts while guiding safe exits.

- Offshore Platforms & Marine Facilities – Withstanding salt spray, vibrations, and extreme marine conditions.

- Industrial Processing Facilities – Supporting safe egress for workers in power plants, steel mills, and manufacturing plants.

- Mining Operations – Offering dependable illumination in underground and dusty environments.

In all these industries, safe evacuation is the difference between life and death, and explosion proof exit lights are designed to deliver exactly that.

Benefits of Explosion Proof Exit Lights

- Enhanced Safety – Ensures personnel can clearly locate emergency exits, even in smoke-filled or dark conditions.

- Regulatory Compliance – Meets or exceeds ATEX, IECEx, UL, and IP66/67 standards for hazardous environments.

- Long-Term Reliability – Built from corrosion-resistant metals and impact-resistant polycarbonate for durability.

- Energy Efficiency – High-performance LEDs reduce operational costs while extending lifespan.

- Uninterrupted Operation – Emergency battery backup guarantees continuous visibility during power failures.

Contact Information:

- Website: sensor-control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100