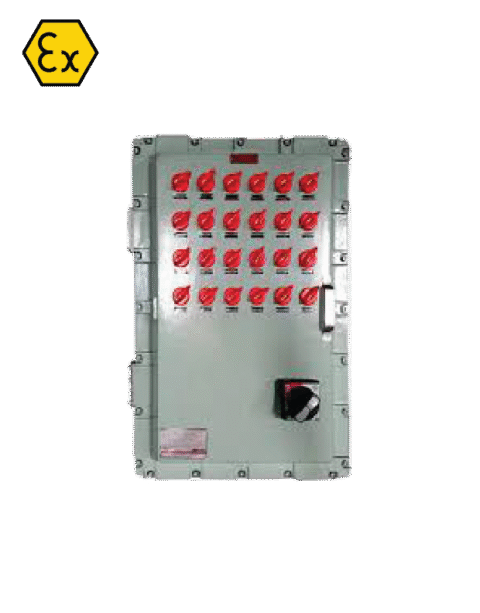

Explosion Proof Distribution Board – Technical & Commercial Guide

1. Core Definition & Design Principle

An explosion-proof distribution board is an enclosure designed to safely distribute electrical power in areas where flammable gases, vapors, or combustible dusts may be present. The explosion proof designation means the housing can contain and cool any internal arc, spark, or explosion, preventing it from igniting the surrounding hazardous atmosphere. This is achieved through robust, certified flameproof (Ex d) construction with precision-machined flanges and durable materials like cast aluminum or stainless steel.

2. Key Specifications & Certifications

When selecting an explosion-proof distribution board, the following specifications are critical:

Electrical Ratings: Common specifications include a rated voltage of 415V AC, 50Hz and a rated current up to 63A. Total connected load is often managed below 350W to control thermal buildup.

Certifications: Must carry international markings:

ATEX (EU Directive 2014/34/EU)

IECEx (International)

UL/CSA (North America)

Regional approvals like ESMA (UAE) or SASO (KCC).

Protection Codes: Look for Ex d IIC T4/T6 for gases and Ex tb IIIC for dust.

Ingress Protection: Minimum IP66/IP67 for dust-tight and water-resistant operation.

3. Product Models & Variants

Manufacturers offer various models tailored to specific needs. A typical explosion-proof distribution board model might follow a naming convention like MAMX-2B8-D, indicating:

Modular design (MAMX)

Dual inputs (2)

8 protected ways (B8)

Digital monitoring (D)

Compact sizes like the B8 form factor are common for limited spaces, while larger boards support more circuits.

4. Advanced Features

Modern explosion-proof distribution boards integrate advanced functionalities:

Dual-Channel Input: Redundant power feeds (e.g., 2 × 63A) with auto-changeover for critical applications.

Modular Protection: Configurable MCBs (Miniature Circuit Breakers), typically 6A–10A per way.

Intelligent Monitoring: Built-in sensors for voltage, current, temperature, and communication via Modbus, Ethernet/IP, or PROFIBUS.

Environmental Durability: Operates across extreme **temperatures (-40°C to +70°C)**, resists corrosion, and withstands vibration.

5. Applications in Hazardous Industries

The explosion proof distribution board is essential in sectors such as:

Oil & Gas: Powering instrumentation, control panels, and safety systems on drilling rigs, refineries, and pipelines.

Chemical & Pharmaceutical: Distributing power in processing areas with solvents or combustible powders.

Utilities: Managing power in pump stations, desalination plants, and fuel depots.

Mining: Providing safe power distribution in underground tunnels with combustible dust.

6. Installation & Compliance

Installing an explosion-proof distribution board requires careful planning:

Area Classification: Match the board’s certification (Zone 1/2, Division 1/2) to the site’s hazard classification.

Certified Installation: Must be performed by qualified electricians using Ex d cable glands and sealed conduits.

Thermal Management: Adhere to the specified total load (<350W) to prevent overheating inside the enclosure.

Documentation: Ensure full certification dossiers, including Declaration of Conformity and installation drawings, are provided.

7. Why Source from a Top UAE Supplier

Partnering with a leading regional supplier for your explosion-proof distribution board offers distinct advantages:

Local Stock: Faster delivery and reduced lead times for urgent projects.

Regional Expertise: Understanding of local climate challenges (heat, sand, humidity) and grid standards (415V, 50Hz).

Technical Support: Assistance with load calculations, gland selection, and system integration.

Compliance Assurance: Guarantee of proper certification for UAE and GCC regulations.

8. Market & Selection Considerations

When procuring an explosion-proof distribution board, consider:

Total Cost of Ownership: Includes unit price, certified installation, and long-term maintenance.

Future-Proofing: Select boards with communication capabilities and modular design for easy expansion.

Vendor Reputation: Choose established suppliers with proven track records in hazardous area equipment.

Conclusion

An explosion-proof distribution board is a foundational component for safe and reliable electrical distribution in hazardous locations. By prioritizing certified safety features, intelligent monitoring, and robust construction, these boards protect personnel, critical assets, and operational continuity. For projects in the Middle East, sourcing from an experienced UAE-based supplier ensures compliance, rapid deployment, and ongoing technical support tailored to regional requirements.

Contact Information:

- Website: sensor-control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100