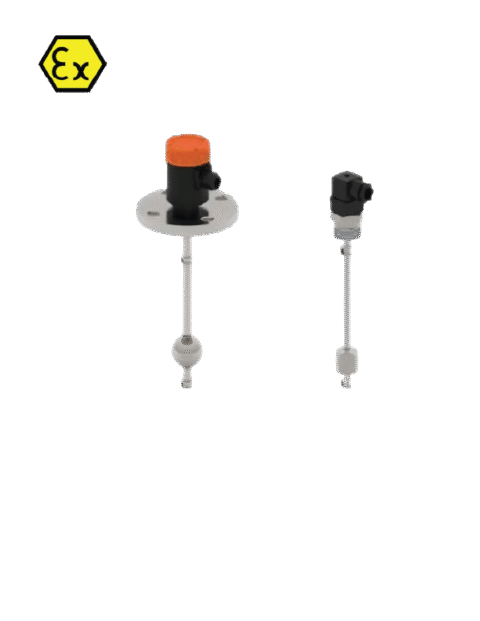

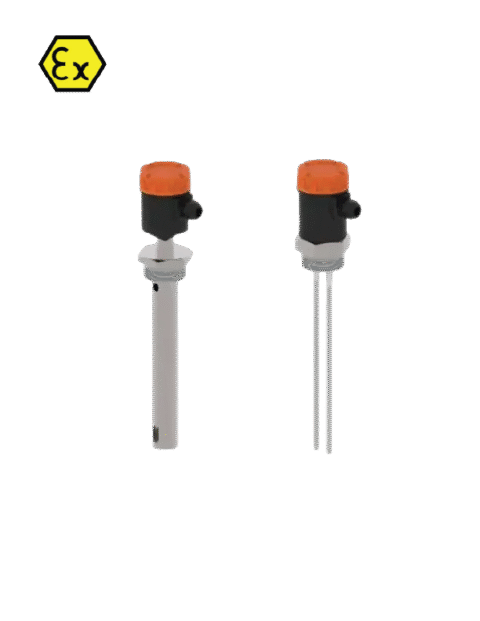

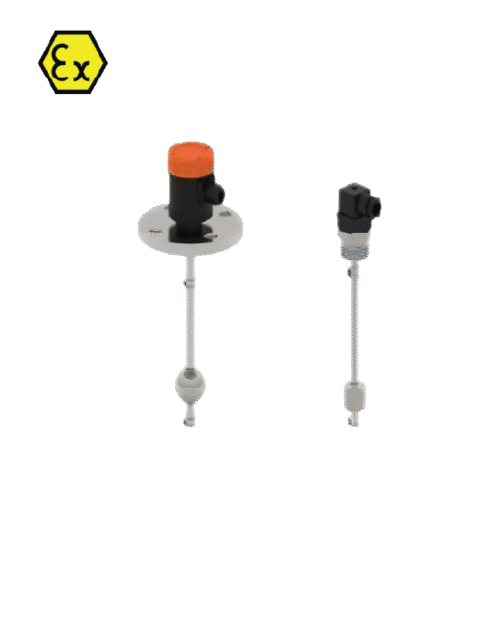

DX-ELS-tx Magnetic Float Level Sensor – Precision, Durability, and Intelligent Level Monitoring

Reliable Level Measurement for Every Industrial Application

Accurate liquid level measurement is critical in industrial systems, from storage tanks and process control to hydraulic systems and wastewater management. The Magnetic Float Level Sensor offers a dependable, precise, and cost-effective solution designed to deliver stable performance under a variety of demanding conditions.

This advanced sensor operates on a proven magnetic float principle, ensuring accurate level detection and continuous monitoring with excellent reliability. Its rugged stainless-steel construction, flexible configurations, and analog output compatibility make it suitable for a wide range of industrial and marine applications.

Working Principle

The DX-ELS-tx magnetic float level sensor works on the simple yet highly reliable interaction between a magnet-equipped float and a reed sensor. As the liquid level in a tank or vessel rises or falls, the float moves accordingly along a guide tube. Within the tube, multiple reed switches and precision resistors are serially aligned.

When the magnetic field of the float comes close to the reed sensor, it triggers the switch — either opening or closing the electrical circuit depending on its configuration. The resistance value changes continuously according to the liquid level, allowing the system to generate an accurate analog signal (typically 4–20 mA).

This signal can be easily integrated with control panels, relay circuits, or automation systems for real-time level indication, process monitoring, or alarm activation.

The lower the placement range of the reed sensor, the higher the precision of the measurement, allowing users to obtain smooth and accurate readings even in sensitive process environments. Additionally, the unit supports local indication via an optional display, making it possible to follow and control the process directly in the field without the need for external equipment.

Key Advantages

- Versatile Material Selection:

Available in 304 Stainless Steel (standard) and 316 Stainless Steel (optional) versions, ensuring high resistance to corrosion, chemicals, and temperature variations. Suitable for use with various liquids including water, oil, chemicals, and fuels. - High Temperature Capability:

Designed to operate reliably up to 125°C, making it ideal for boiler systems, hot water tanks, and industrial process control. - Flexible Output Options:

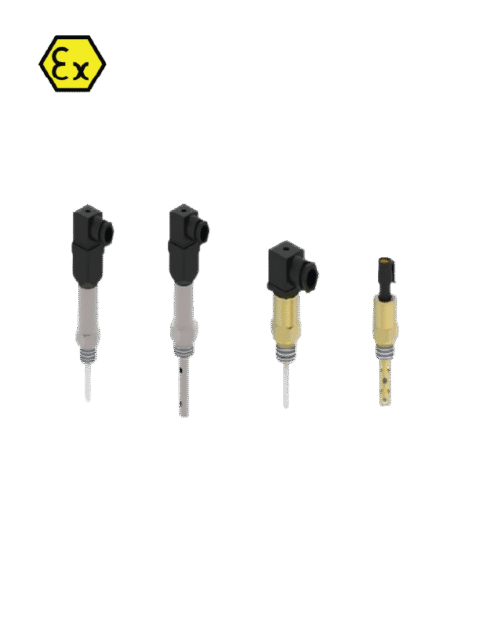

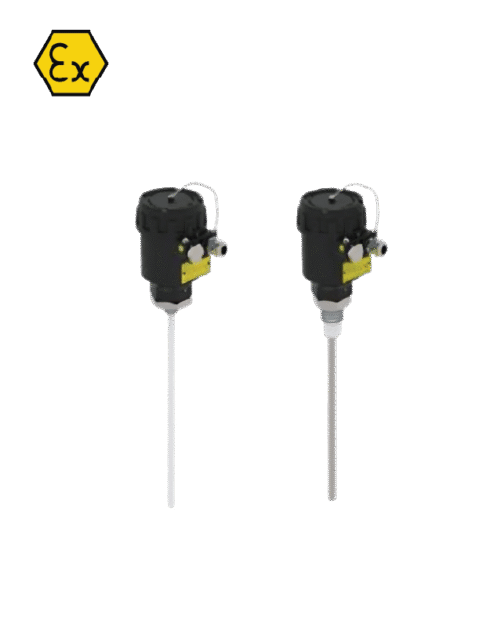

Standard 4–20 mA two-wire output for easy integration into existing control systems. Optional output formats include 0–20 mA, 0–10 V, or Ohm, as well as three-wire configurations for specific application requirements. - Different Ignition and Connection Options:

Choose from terminal connection, cable connection, or socket connection depending on the installation environment and maintenance preferences. - Precision & Stability:

High measurement accuracy with resolution options of 15 mm, 10 mm, or 5 mm, providing smooth, stable, and precise analog signals. - Customizable Lengths:

Standard models available up to 6000 mm (including thread). Lengths can be customized based on tank height and application needs. - Rugged and Reliable Protection:

Protection class IP66 or IP68, ensuring full resistance against dust, moisture, and submersion, guaranteeing dependable operation in harsh industrial environments. - Quick Delivery & Technical Flexibility:

Available in multiple configurations with fast delivery times and custom technical adaptations, making it easy to select the right model for your specific process.

Applications

The Magnetic Float Level Sensor is designed for universal liquid level measurement and control across various industries, including:

- Industrial Tanks: Monitoring and control of liquid levels in storage and process tanks.

- Boilers: Accurate water level control in industrial and domestic boiler systems.

- Sewage & Wastewater: Reliable level detection in sewage systems and wastewater treatment plants.

- Marine Applications: Ideal for yacht water level control and ship fuel or ballast monitoring.

- Hydraulic Systems: Measuring and maintaining oil levels in hydraulic reservoirs and machinery.

- Storage Rooms & Warehouses: Tank level control for industrial storage systems and utility management.

Whether it’s clean water, oil, chemicals, or wastewater — the sensor provides consistent performance even in challenging environments.

Why Choose Our Magnetic Float Level Sensor?

- High Accuracy and Repeatability:

Delivers stable output even with continuous liquid motion, ensuring precise control of tank levels. - Maintenance-Free Design:

No moving parts inside the tube other than the float — minimizes wear and maintenance costs. - Analog Output Convenience:

Directly compatible with PLCs, control systems, and alarm modules for automatic process control. - Custom Engineering:

Tailored solutions for different tank sizes, mounting methods, and electrical outputs. - Durable and Long-Lasting:

Built with industrial-grade stainless steel and sealed components for long service life even in harsh environments. - Safety and Reliability:

Explosion-proof and corrosion-resistant options available for critical industries such as chemical, oil & gas, and marine sectors.

Ideal for Modern Industrial Automation

With increasing demand for smart process monitoring and automation, this sensor provides the right blend of accuracy, durability, and connectivity. Whether used as a standalone level transmitter or integrated into a complex control system, it ensures dependable level information and alarm signaling to prevent overflow, dry-run, or process failure.

The Magnetic Float Level Sensor not only ensures smooth process operation but also reduces downtime, enhances safety, and extends equipment life.

Contact Information:

- Website: sensor-control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100

Reviews

There are no reviews yet.