Comprehensive Guide to Rezontech Flame Detectors

Industrial facilities and hazardous environments face significant risks from fires, with devastating consequences. Rezontech Flame Detectors play a critical role in mitigating these risks by providing early detection and warning systems.

Rezontech Flame Detectors are designed to detect fires quickly and accurately, minimizing damage and ensuring the safety of personnel and equipment. This comprehensive guide will cover the various models of Rezontech Flame Detectors, their applications, and the importance of selecting the right detector for specific industrial needs.

Key Takeaways

- Understanding the role of Rezontech Flame Detectors in industrial safety

- Overview of different Rezontech Flame Detector models and their applications

- Importance of proper installation and maintenance of flame detection systems

- Guidelines for selecting the appropriate Rezontech Flame Detector for specific industrial environments

- Best practices for integrating Rezontech Flame Detectors into existing safety protocols

The Critical Role of Flame Detection in Industrial Safety

In industrial environments, the role of flame detection cannot be overstated, as it directly impacts the safety of personnel and equipment. Flame detectors, particularly those utilizing UV/IR technology, are crucial in identifying potential fire hazards before they escalate.

Understanding Fire Hazards in Industrial Environments

Industrial settings often involve processes and materials that can be highly flammable, creating an environment where fires can start and spread rapidly. The presence of combustible materials, coupled with potential ignition sources, heightens the risk of fire-related accidents.

How Early Detection Prevents Catastrophic Events

Early detection of flames is critical in preventing minor incidents from becoming major catastrophes. UV/IR flame detectors are designed to identify fires quickly, allowing for swift intervention and minimizing potential damage.

Regulatory Requirements for Fire Detection Systems

Industrial facilities are subject to stringent regulations regarding fire safety, including the implementation of effective flame detection systems. Compliance with these regulations is not only mandatory but also essential for ensuring a safe working environment.

The use of advanced flame detector technology, such as UV/IR detection, is a key component in meeting these regulatory requirements and enhancing overall industrial safety.

How Flame Detector Technology Works

Understanding how flame detectors work is essential for appreciating their value in preventing industrial accidents. Flame detectors are sophisticated devices designed to identify fires at their earliest stages, thereby enabling swift action to mitigate potential damage.

The Science Behind Different Detection Methods

Flame detectors employ various technologies to detect fires. The primary methods include Ultraviolet (UV) detection, Infrared (IR) detection, and combined UV/IR detection. Each method has its strengths and is suited to different environments.

UV detection involves sensing the ultraviolet radiation emitted by flames. This method is highly sensitive and can detect fires quickly. However, it can be prone to false alarms due to other sources of UV radiation.

IR detection, on the other hand, identifies the infrared radiation emitted by fires. IR detectors are less susceptible to false alarms than UV detectors but can be affected by hot surfaces or sunlight.

UV, IR, and Combined UV/IR Technologies

Combining UV and IR technologies offers a more robust detection method. UV/IR flame detectors can identify both the UV and IR radiation emitted by flames, reducing the likelihood of false alarms. This combined approach enhances the reliability of flame detection, making it suitable for a wide range of industrial applications.

- UV detection for fast response

- IR detection for immunity to false alarms

- Combined UV/IR for enhanced reliability

False Alarm Prevention Mechanisms

False alarms can lead to unnecessary downtime and costs. Modern flame detectors incorporate various mechanisms to prevent false alarms, including advanced signal processing algorithms and multi-spectral detection technologies.

For instance, some flame detectors use Triple IR technology, which detects fires by analyzing the radiation in three different IR bands. This approach significantly reduces false alarms caused by non-fire sources.

“The key to effective flame detection lies not just in identifying fires, but in doing so with minimal false alarms, thereby ensuring continuous operation without unnecessary interruptions.”

By understanding the different technologies and mechanisms employed by flame detectors, industries can better select and implement fire safety solutions tailored to their specific needs.

Introducing Rezontech’s Advanced Flame Detector Portfolio

With a strong foundation in engineering excellence, Rezontech introduces its advanced flame detector portfolio, setting new standards in fire safety. The company’s commitment to innovation and quality is reflected in its comprehensive range of flame detectors designed to protect lives and assets in various industrial environments.

Company Background and Engineering Excellence

Rezontech is a renowned leader in the field of industrial safety solutions, with a history of delivering high-quality products that meet the evolving needs of industries worldwide. The company’s engineering team is comprised of experts who leverage the latest technologies to develop flame detectors that are not only effective but also reliable and durable. “Our mission is to provide the most advanced and reliable flame detection solutions that save lives and protect critical infrastructure,” says a Rezontech spokesperson.

The company’s dedication to engineering excellence is evident in its state-of-the-art manufacturing facilities and rigorous testing protocols, ensuring that every flame detector meets the highest standards of performance and reliability.

Certification Standards and Compliance

Rezontech’s flame detectors are designed and manufactured in compliance with international safety standards, including UL, FM, and ATEX certifications. These certifications underscore the company’s commitment to delivering products that meet or exceed global safety requirements. By adhering to these stringent standards, Rezontech ensures that its flame detectors provide unparalleled detection capabilities and immunity to false alarms.

Overview of Product Lines and Technologies

Rezontech’s flame detector portfolio encompasses a wide range of models, each designed to address specific fire safety needs across different industries. From the RFD-5000X UV/IR Flame Detector to the advanced RFD-6000X model, Rezontech’s products incorporate cutting-edge technologies such as UV, IR, and combined UV/IR detection methods. These technologies enable the detectors to identify fires quickly and accurately, minimizing the risk of false alarms.

The company’s product lines are designed to cater to various application scenarios, including harsh environments and areas with high false alarm sources. By offering a diverse range of flame detectors, Rezontech enables businesses to select the most appropriate solutions for their specific safety requirements.

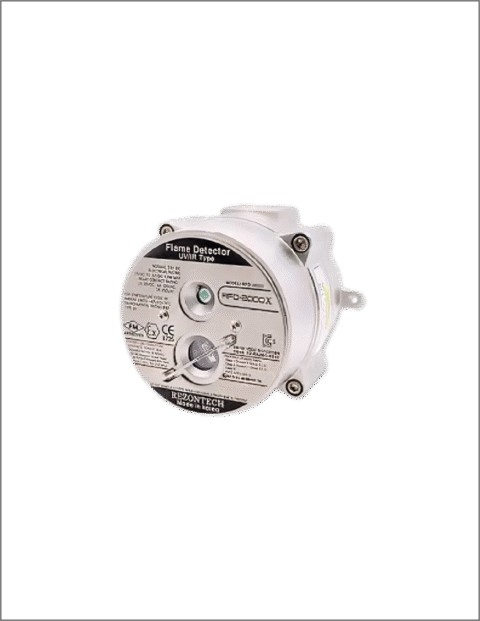

The RFD-5000X UV/IR Flame Detector: Features and Applications

With its advanced UV/IR detection capabilities, the RFD-5000X is designed for high-risk industrial environments where the swift and accurate detection of fires is paramount.

Technical Specifications and Detection Capabilities

The RFD-5000X boasts impressive technical specifications that enhance its detection capabilities. Key features include:

Detection Range and Field of View

The RFD-5000X offers a wide detection range and a broad field of view, ensuring comprehensive coverage of the monitored area. This enables the detector to identify potential fires from various angles and distances.

Environmental Tolerances

Designed to operate effectively in challenging environments, the RFD-5000X is engineered to withstand extreme temperatures, humidity, and other environmental factors. This resilience ensures consistent performance and reliability.

Physical and Electrical Specifications

The detector’s robust design and electrical specifications ensure seamless integration into existing safety systems. Its physical attributes are tailored for easy installation and maintenance.

Ideal Implementation Scenarios

The RFD-5000X UV/IR flame detector is ideal for various industrial settings, including oil and gas facilities, chemical plants, and power generation sites. Its advanced detection capabilities make it a valuable asset in preventing catastrophic events.

By selecting the RFD-5000X, facilities can enhance their fire safety measures, ensuring a safer working environment for employees and reducing the risk of damage to equipment and infrastructure.

Exploring the High-Performance RFD-6000X Model

With its advanced features and improved specifications, the RFD-6000X stands out as a premier choice for industrial flame detection. This model builds upon the successes of its predecessors, offering enhanced performance and reliability.

Advanced Features and Technical Specifications

The RFD-6000X flame detector boasts several key advancements, including improved detection ranges and enhanced false alarm immunity. Its technical specifications highlight a robust design capable of withstanding harsh industrial environments.

Key Features: – Enhanced UV/IR detection technology – Wider detection range – Improved resistance to false alarms – Robust design for harsh environments

Performance Improvements Over the 5000X Series

The RFD-6000X model represents a significant upgrade over the RFD-5000X series, with notable improvements in detection speed and accuracy. The table below outlines some of the key differences:

| Feature | RFD-5000X | RFD-6000X |

|---|---|---|

| Detection Range | Up to 100 meters | Up to 150 meters |

| False Alarm Immunity | Good | Excellent |

| Environmental Resistance | Robust | Very Robust |

Best Applications for Maximum Effectiveness

The RFD-6000X is particularly suited for high-risk industrial environments, such as oil and gas facilities, chemical plants, and power generation sites. Its enhanced detection capabilities and reliability make it an ideal choice for applications where safety is paramount.

The 2FTN Series: Comparing RFD-2FTN-H and 2FTN-I Models

The 2FTN series by Rezontech represents a significant advancement in flame detection technology, offering two distinct models: RFD-2FTN-H and 2FTN-I. This comparison will help you understand the unique features and applications of each model.

Key Features and Technical Differences

The RFD-2FTN-H and 2FTN-I models differ in their detection technologies. The RFD-2FTN-H uses a combination of UV and IR sensors, while the 2FTN-I relies on IR technology alone. This difference impacts their performance in various environments.

Key Features Comparison:

| Feature | RFD-2FTN-H | 2FTN-I |

|---|---|---|

| Detection Technology | UV/IR | IR |

| Detection Range | Up to 100 meters | Up to 80 meters |

| False Alarm Immunity | High | Moderate |

Environmental Adaptability and Limitations

The RFD-2FTN-H is more versatile and can operate effectively in a wider range of environments, including those with high levels of sunlight or background radiation. In contrast, the 2FTN-I is better suited for environments with minimal sunlight interference.

Cost-Effectiveness and Value Proposition

While the RFD-2FTN-H is generally more expensive due to its advanced UV/IR technology, it offers a higher level of reliability and false alarm immunity, making it a valuable investment for critical infrastructure. The 2FTN-I, being more cost-effective, is suitable for less demanding applications.

In conclusion, the choice between the RFD-2FTN-H and 2FTN-I models depends on the specific requirements of your facility, including environmental conditions and budget considerations.

RFD-2000X-H and RFD-2000: Standard vs. Enhanced Protection

Rezontech’s RFD-2000X-H and RFD-2000 flame detectors are designed to cater to different industrial safety needs, making the choice between them dependent on specific requirements. Understanding the differences between these models is crucial for ensuring the right level of protection for your facility.

Specification Comparison and Performance Differences

The RFD-2000X-H is an enhanced version of the standard RFD-2000 flame detector, offering advanced features such as improved detection range and enhanced false alarm immunity. The key specifications of both models are compared in the table below:

| Feature | RFD-2000 | RFD-2000X-H |

|---|---|---|

| Detection Range | Up to 100 meters | Up to 150 meters |

| False Alarm Immunity | Standard | Enhanced |

| Operating Temperature | -20°C to +75°C | -40°C to +85°C |

Installation Considerations for Each Model

When installing either model, it’s essential to consider the environmental conditions and the layout of the facility. The RFD-2000X-H, with its enhanced features, may require more complex configuration but offers greater flexibility in challenging environments.

Selecting Between Models Based on Requirements

Choosing between the RFD-2000 and RFD-2000X-H depends on the specific safety needs of your facility. For environments with higher risks or more complex layouts, the RFD-2000X-H may be the better choice due to its enhanced capabilities.

Triple IR Technology in the RFD-3000X and RFD-3000 Series

Rezontech’s RFD-3000X and RFD-3000 series flame detectors utilize advanced triple IR technology for enhanced fire detection. This technology represents a significant advancement in the field, offering improved detection capabilities and reduced false alarms.

The Advantages of Triple IR Detection

The triple IR detection method provides several key advantages over traditional single or dual IR technologies. By analyzing the infrared radiation spectrum at three different wavelengths, these detectors can more accurately identify fires, even in challenging environments.

Key benefits include:

- Enhanced detection accuracy

- Improved resistance to false alarms

- Effective detection in various environmental conditions

Technical Specifications and Capabilities

The RFD-3000X and RFD-3000 series detectors are designed with advanced technical specifications that enable superior performance. These include:

| Specification | RFD-3000X | RFD-3000 |

|---|---|---|

| Detection Range | Up to 100 meters | Up to 80 meters |

| Response Time | < 5 seconds | < 5 seconds |

| Operating Temperature | -40°C to +85°C | -20°C to +75°C |

Specialized Applications and Performance Benefits

The RFD-3000X and RFD-3000 series are particularly suited for applications in harsh environments, such as oil and gas facilities, chemical plants, and power generation facilities. Their robust design and advanced detection technology ensure reliable performance in these demanding settings.

The use of triple IR technology in these detectors not only enhances safety but also provides a cost-effective solution by reducing the likelihood of false alarms and associated downtime.

How to Select the Right Flame Detector for Your Facility

To ensure optimal safety, it’s crucial to select a flame detector that aligns with your facility’s unique hazards and operational parameters. The process involves several key considerations.

Assessing Environmental Conditions and Hazards

The first step is to assess the environmental conditions and potential fire hazards within your facility. This includes understanding the types of fuels present, the layout of the area, and any potential sources of ignition. Environmental factors such as dust, humidity, and extreme temperatures can significantly impact the performance of a flame detector.

Determining Coverage Requirements and Detection Ranges

Next, determine the coverage requirements and detection ranges needed for your facility. This involves calculating the area to be monitored and ensuring that the selected flame detector can effectively cover that area without compromising on detection sensitivity. The detection range of a flame detector is crucial for early fire detection.

Evaluating False Alarm Immunity Needs

False alarms can lead to unnecessary downtime and costs. Therefore, evaluating the false alarm immunity of a flame detector is vital. Look for detectors with advanced algorithms and technologies designed to minimize false alarms while maintaining high sensitivity to actual fires.

Budget Considerations and Return on Investment

Finally, consider your budget and the potential return on investment (ROI) of the flame detector. While cost is an important factor, it’s equally crucial to consider the long-term benefits, including reduced damage from fires, lower insurance premiums, and enhanced safety. Investing in a high-quality flame detector can yield significant long-term savings.

By carefully assessing these factors, you can select a flame detector that not only meets your facility’s safety needs but also provides a strong ROI. The right flame detector is a critical component of a comprehensive fire safety strategy.

Step-by-Step Installation Guide for Rezontech Flame Detectors

To maximize the effectiveness of Rezontech flame detectors, it’s essential to understand the proper installation procedures. A well-planned installation ensures that the detectors function optimally, providing reliable fire detection and safety.

Pre-Installation Planning and Site Assessment

Before installing Rezontech flame detectors, conduct a thorough site assessment to identify potential fire hazards and determine the optimal detector placement. Consider factors such as the type of fuel present, the layout of the area, and any environmental conditions that may affect detector performance.

Proper Mounting and Positioning Techniques

Rezontech flame detectors should be mounted securely to prevent vibration or movement that could affect their accuracy. The detectors should be positioned to provide an unobstructed view of the area being monitored. Consider the height and angle of mounting to ensure optimal coverage.

Wiring and Connection Procedures

Follow the manufacturer’s guidelines for wiring and connecting Rezontech flame detectors. Ensure that all connections are secure and meet the required electrical standards. Proper wiring is crucial for the reliable operation of the detectors.

Commissioning and Initial Testing Protocol

After installation, commission the Rezontech flame detectors according to the manufacturer’s instructions. Perform initial testing to verify that the detectors are functioning correctly and responding to simulated fire conditions.

Documentation and Compliance Verification

Maintain detailed records of the installation, including detector placement, wiring diagrams, and test results. Verify that the installation complies with relevant regulatory requirements and industry standards.

| Installation Step | Description | Verification |

|---|---|---|

| Pre-Installation Planning | Conduct site assessment and identify potential fire hazards | Site assessment report |

| Mounting and Positioning | Securely mount detectors with optimal positioning | Installation photos |

| Wiring and Connection | Follow manufacturer’s wiring guidelines | Wiring diagrams |

| Commissioning and Testing | Commission detectors and perform initial testing | Test results |

Conclusion

Selecting and installing the right flame detection system is crucial for ensuring industrial safety. Rezontech flame detectors play a vital role in preventing catastrophic events by providing early detection of fires. The comprehensive guide has outlined the critical role of flame detection, the technology behind different detection methods, and the various models available in Rezontech’s portfolio.

The RFD-5000X, RFD-6000X, and 2FTN series are among the advanced flame detectors discussed, each with unique features and applications. Understanding the technical specifications, detection capabilities, and environmental adaptability of these models is essential for making an informed decision.

By assessing environmental conditions, determining coverage requirements, and evaluating false alarm immunity needs, industries can choose the most suitable flame detector for their facility. Proper installation, as outlined in the step-by-step guide, ensures optimal performance and compliance with regulatory requirements.

Rezontech flame detectors offer a reliable solution for industrial fire safety, providing peace of mind and protection against potential hazards. By investing in the right flame detection system, industries can safeguard their assets, personnel, and operations.

FAQ

What is the difference between a UV flame detector and an IR flame detector?

UV flame detectors detect the ultraviolet radiation emitted by a fire, while IR flame detectors detect the infrared radiation. UV detectors are more resistant to false alarms from hot objects, while IR detectors can detect fires through smoke and are less prone to false alarms from sunlight.

How does a UV/IR flame detector work?

A UV/IR flame detector combines the benefits of both UV and IR detection technologies. It detects both the UV and IR radiation emitted by a fire, providing a more reliable and accurate detection of fires while minimizing false alarms.

What are the advantages of using a triple IR flame detector?

Triple IR flame detectors use three IR sensors to detect fires, providing a high level of immunity to false alarms. They are particularly effective in detecting fires in environments with high levels of sunlight or other sources of IR radiation.

How do I choose the right flame detector for my facility?

To choose the right flame detector, consider factors such as the type of fire hazards present, environmental conditions, detection range, and false alarm immunity. Rezontech’s range of flame detectors, including UV, IR, and UV/IR models, can be tailored to meet specific facility requirements.

What are the key considerations for installing a flame detector?

Key considerations include proper mounting and positioning, wiring and connection procedures, and commissioning and initial testing. Rezontech provides a step-by-step installation guide to ensure correct installation and optimal performance.

How can I ensure the optimal performance of my flame detector?

Regular testing and maintenance are crucial to ensure the optimal performance of your flame detector. Follow the manufacturer’s guidelines for testing and maintenance, and consider factors such as environmental conditions and detection range.

What is the detection range of Rezontech flame detectors?

The detection range of Rezontech flame detectors varies depending on the model. For example, the RFD-5000X UV/IR flame detector has a detection range of up to 100 feet. Refer to the specific product documentation for detailed information on detection range and field of view.

Are Rezontech flame detectors certified to industry standards?

Yes, Rezontech flame detectors are certified to relevant industry standards, ensuring compliance with regulatory requirements. Check the specific product certification and compliance information for details.

Contact Information:

- Website: sensor-control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100