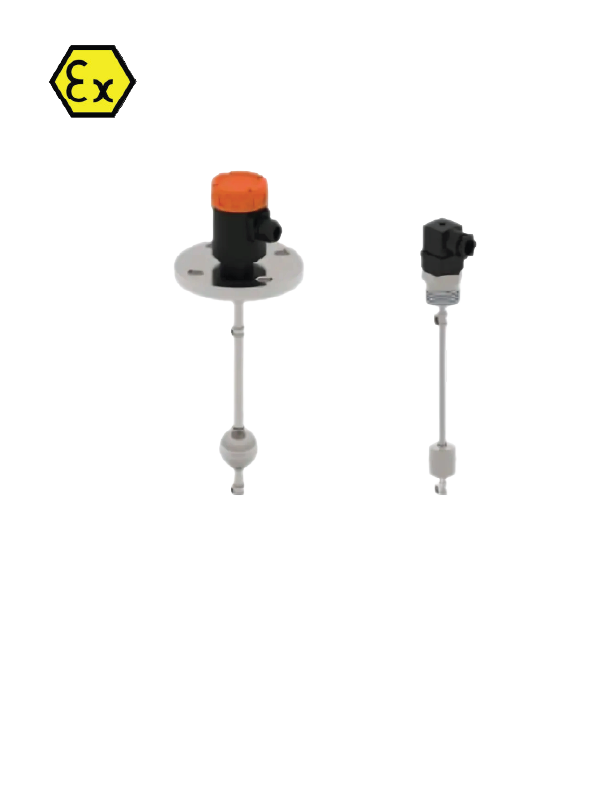

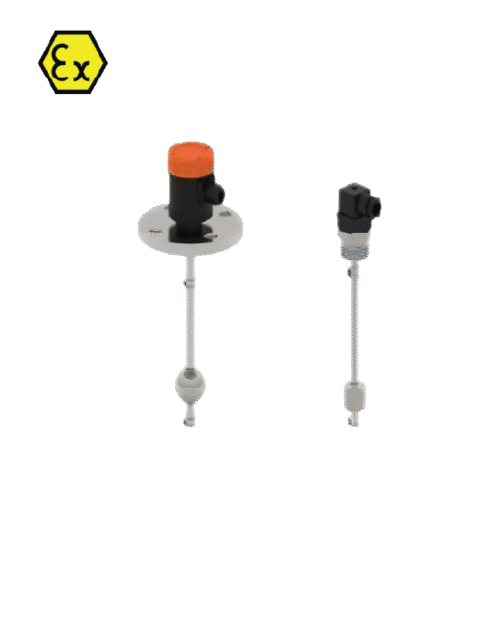

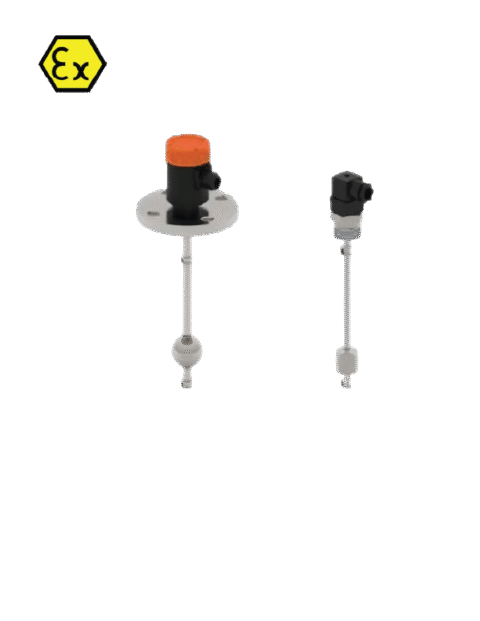

ELS Float Level Sensors – Reliable and Accurate Liquid Level Measurement Solutions

The ELS Level Sensor is a high-performance magnetic float-type level switch designed for precise and reliable liquid level monitoring and control in a wide range of industrial and commercial applications. Known for its durability, versatility, and ease of installation, this sensor provides dependable level detection for tanks, vessels, and containers holding liquids of various properties — from water and hydraulic oil to chemicals and fuels.

Built with high-quality materials and designed with advanced engineering, the ELS Level Sensor offers exceptional stability and accuracy even in demanding environments such as high temperature, high pressure, or corrosive conditions. Whether for boiler systems, sewage plants, or marine applications, it ensures safe and efficient operation with minimal maintenance.

Working Principle

The ELS Level Sensor operates based on a magnetic float and reed switch principle. A float containing a permanent magnet moves vertically along a guiding tube as the liquid level rises or falls inside the tank. Inside the tube are hermetically sealed reed switches placed at defined points.

When the float’s magnet comes in proximity to a reed switch, the magnetic field activates the switch, either opening or closing the circuit. This change in the electrical state can be transmitted to an indicator, controller, or relay to perform specific actions — such as triggering an alarm, starting or stopping a pump, or sending a signal to a control panel.

This simple yet highly effective mechanism ensures precise level detection without any mechanical contact between the sensing element and the liquid, thus ensuring long operational life and high reliability even in harsh conditions.

Construction and Design

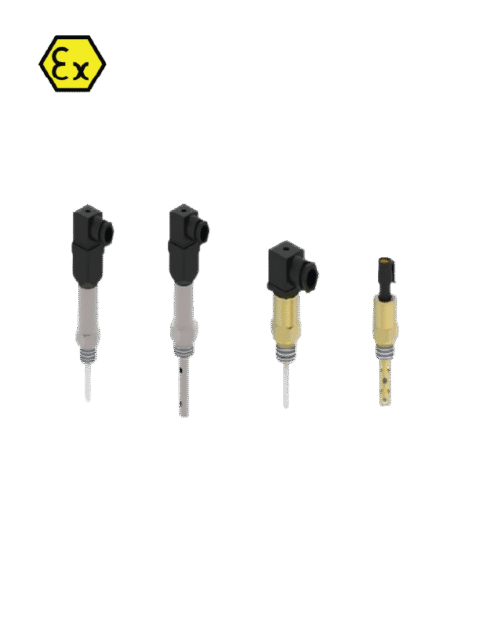

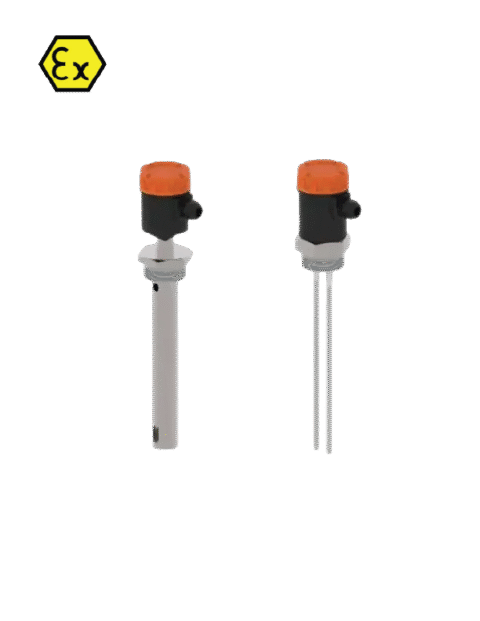

The ELS Level Sensor is constructed with robust materials suitable for various process conditions. It can be manufactured using stainless steel, brass, or engineering plastics (like PVC or PP) depending on the application and liquid type.

The housing and float materials can be selected according to the nature of the liquid — whether corrosive, viscous, or high-temperature. Each unit is customizable to meet specific process requirements, including length, mounting type, electrical connections, and output configurations.

The sealed reed switches ensure no direct electrical contact with the liquid, providing spark-free operation and enhanced safety in hazardous or explosive environments. The hermetic sealing also prevents oxidation, moisture entry, and mechanical wear.

- Reliable Working Principle:

Operates on a magnetic float and reed switch system — ensuring accurate, contactless, and maintenance-free liquid level detection. - Durable Construction:

Made from high-quality materials like stainless steel, brass, or plastic to suit different liquids, including corrosive and high-temperature ones. - Built-in Relay Output:

Comes with an integrated relay in the housing for direct control of pumps, alarms, or valves — simplifying installation and wiring. - Wide Application Range:

Suitable for tank level control, boiler systems, sewage plants, marine tanks, and hydraulic systems, among others. - User Advantages:

Offers customizable design, fast delivery, explosion-proof options, and reliable performance for long-term use in industrial environments.

Information:

- Website: sensor-control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100

Reviews

There are no reviews yet.