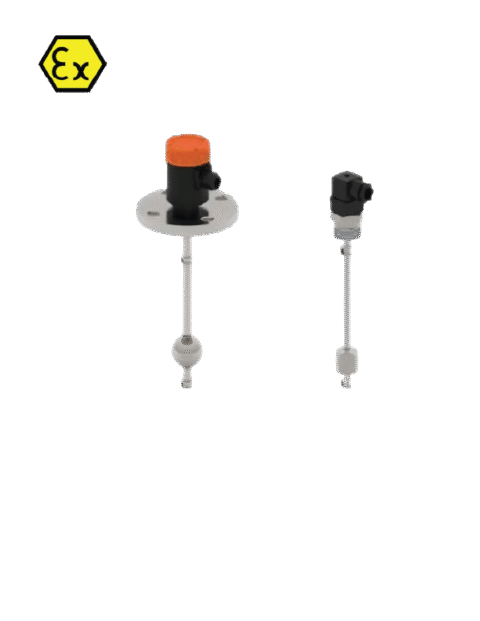

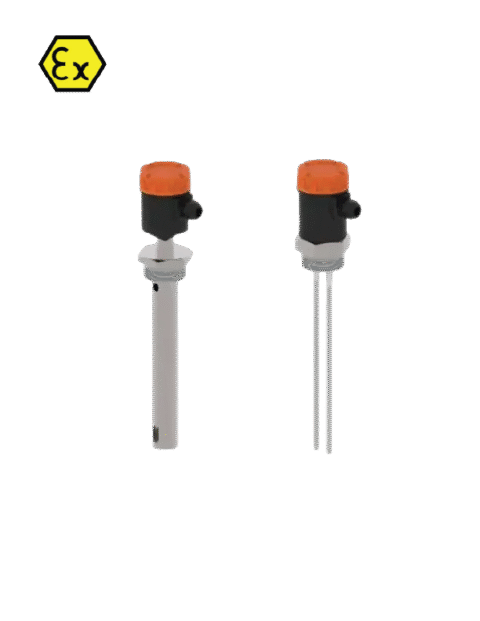

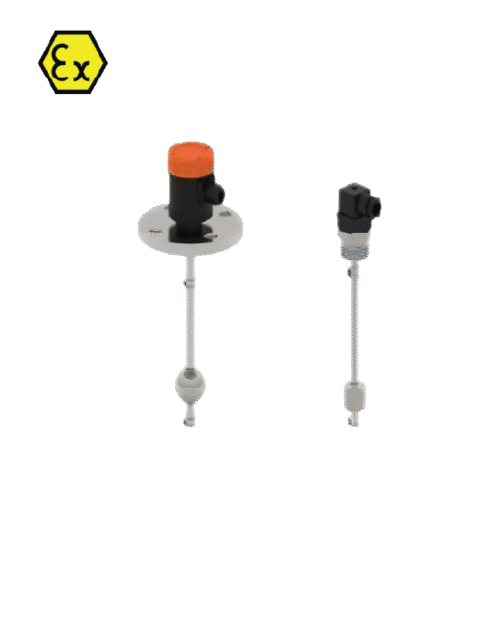

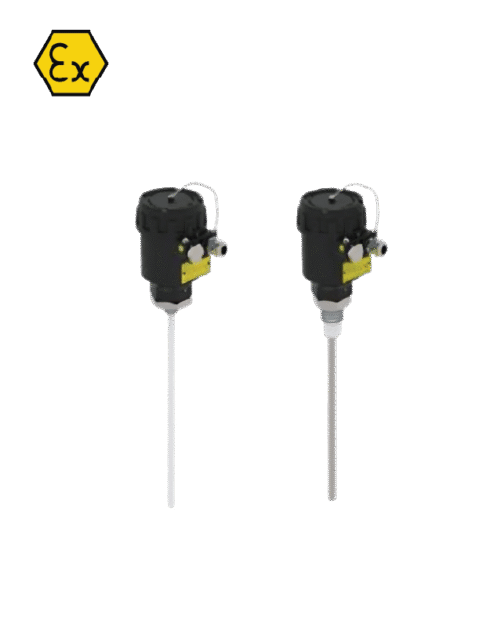

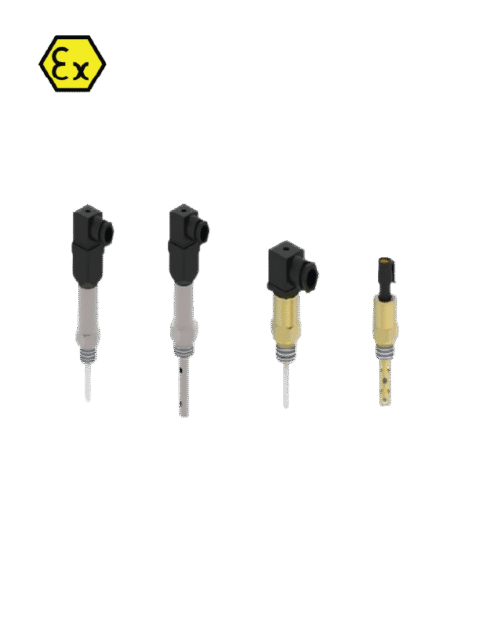

ECASm / ECASe / ECAM – Advanced OEM Capacitive Level Sensors for Liquids and Solids

The ECASm / ECASe / ECAM series of OEM capacitive type level sensors represent a new standard in precision level measurement technology. These high-performance sensors are designed for detecting and monitoring levels of liquids, solids, and semi-solids, including both conductive and non-conductive materials. With robust construction, advanced sensing electronics, and superior adaptability, the ECAS series provides accurate, stable, and maintenance-free performance across a wide range of industrial and commercial applications.

Whether installed in tanks, silos, or process lines, these sensors are engineered to deliver maximum reliability even in the most challenging environments involving vibration, high temperature, pressure, or aggressive chemicals.

Working Principle

The ECASm / ECASe / ECAM capacitive level sensors operate based on the principle of capacitance variation. Each sensor consists of a probe electrode and a reference point (the tank wall or ground). The material between them acts as a dielectric medium.

As the level of the medium rises or falls, the capacitance value changes proportionally. The internal electronics detect this change and convert it into an output signal—relay or transistor—triggering external devices like pumps, alarms, or control systems.

Because this measurement principle does not rely on mechanical movement, the ECAS sensors provide non-contact, highly sensitive, and wear-free operation, ideal for long-term use in harsh industrial conditions.

Application Versatility

The ECASm / ECASe / ECAM sensors are suitable for virtually all types of media, including:

-

- Conductive liquids: Water, brine, glycol, wastewater, and other process fluids.

- Non-conductive liquids: Oils, fuels, refrigerants, and solvents.

- Solids and particulate materials: Grain, cement, sand, feed, flour, milk powder, organic or plastic granules.

- Adhesive and corrosive materials: Acids, bases, hot viscous liquids, and sticky chemical substances.

This versatility makes the ECAS series ideal for use in chemical processing, food and beverage plants, wastewater management, energy production, marine systems, and storage facilities.

Electrical Characteristics

The sensors operate on a 10–30 VDC supply voltage (maximum 35 VDC), ensuring compatibility with most industrial control systems. They offer multiple output configurations:

-

- Relay output: 1 NO/NC contact rated at 5A / 250 VAC, with an adjustable 2-second delay for stable switching.

- Transistor output: NPN or PNP open collector type, selectable as NO or NC (defined when ordering).

This flexibility allows seamless integration with programmable logic controllers (PLCs), distributed control systems (DCS), and standalone monitoring setups.

The capacitance measurement range extends from 1 pF to 3 nF, supporting a wide range of materials and tank geometries. Typical accuracy lies between ±0.5% to ±5%, depending on the model, with excellent linearity at 0.5%.

With low power consumption (max 1 W, 50 mW for transistor models), these sensors ensure energy-efficient operation without sacrificing performance.

Mechanical Design and Materials

Every component of the ECAS series has been carefully selected for strength, corrosion resistance, and temperature stability.

-

- Sensor body: Made from 304 stainless steel as standard, with optional 316 stainless steel for aggressive or marine environments.

- Insulation materials: Include PTFE, PFA, PVDF, Delrin, Peek, and Ceramic, chosen for their superior dielectric strength and chemical resistance.

- Housing: Available in aluminum or high-strength plastic, providing excellent durability and lightweight handling.

- Process connection: Standard 1/2″ BSP male thread, ensuring universal compatibility with industrial installations.

This robust mechanical construction ensures long-term reliability, even in applications involving corrosive media, abrasive solids, or high vibration.

Pressure and Temperature Capabilities

The ECASm / ECASe / ECAM sensors are built to operate under extreme conditions:

-

- Operating temperature: –30°C to +150°C (standard)

- With cooling apparatus: Up to 200°C

- With Peek isolation: Up to 230°C

- Working pressure: Up to 150 bar, depending on model

- Ambient temperature: –20°C to +80°C

These specifications make them suitable for high-pressure systems, high-temperature reactors, and refrigerated or cryogenic tanks. Even under rapid temperature changes, the sensors maintain stable and accurate performance without drift or signal loss.

Installation and Connectivity

The ECASm / ECASe / ECAM sensors are designed for easy installation and integration into existing process systems.

Electrical connections are available in several formats to suit various requirements:

-

- Terminals for fixed panel wiring

- ISO 4400 (DIN 43650) connectors for plug-and-play connections

- Cable gland connections for sealed outdoor installations

Mechanical connections use standard 1/2″ BSP male threads, allowing installation into threaded tank fittings or process ports. Tightening torques range from 10 Nm to 40 Nm, depending on the version.

The sensors are rated IP65 or IP67 (EN60529), ensuring resistance to dust, moisture, and water jets. This makes them ideal for outdoor use or washdown environments such as food processing facilities.

Advantages

The ECASm / ECASe / ECAM capacitive sensors provide several key operational benefits that make them superior to conventional level switches:

-

- Customer Calibratable: Users can easily calibrate sensitivity and switching points on-site without factory adjustment.

- No Moving Parts: Ensures zero mechanical wear and maintenance-free operation.

- Vibration Resistant: Unaffected by mechanical vibrations or shocks.

- Full-Length Measurement: The entire probe acts as an active sensing element, improving accuracy.

- High Pressure & Temperature Resistance: Ensures performance reliability in harsh conditions.

- Insensitive to Foam or Coating: Maintains accurate readings even when the probe is covered by foam, splashes, or sticky substances.

- Compact & Easy to Install: Lightweight, modular design for convenient mounting and servicing.

- Energy Efficient: Low power draw enhances system efficiency.

These advantages make ECAS sensors a cost-effective and durable solution for industrial level measurement and control.

Application Areas

The ECASm / ECASe / ECAM sensors are used extensively in:

-

- Liquid tanks (water, oil, glycol, CO₂, brine, wastewater)

- Food machines and cooling systems

- Chemical tanks containing acids, bases, or solvents

- Silos and hoppers for grain, flour, cement, or plastic granules

- High-viscosity and adhesive materials in industrial processing

These models serve as a universal level measurement solution, combining precision, durability, and adaptability in one device.

Information:

- Website: sensor-control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100

Reviews

There are no reviews yet.