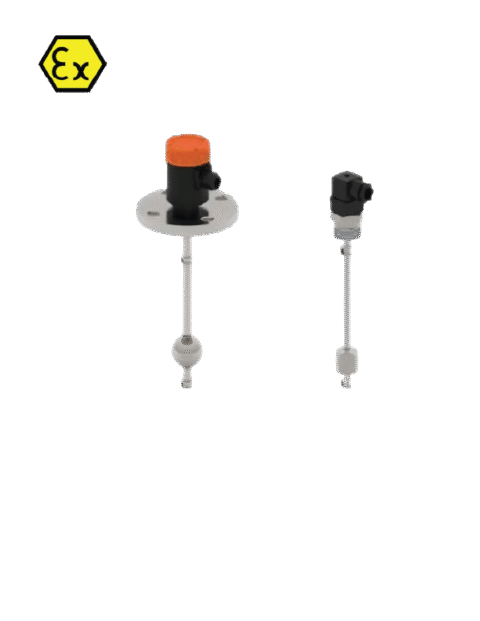

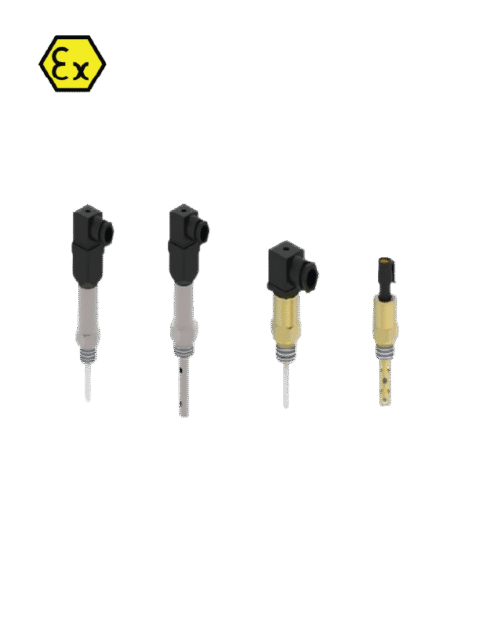

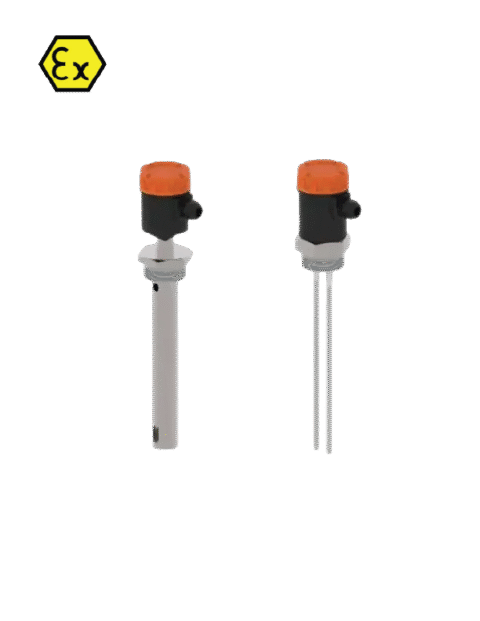

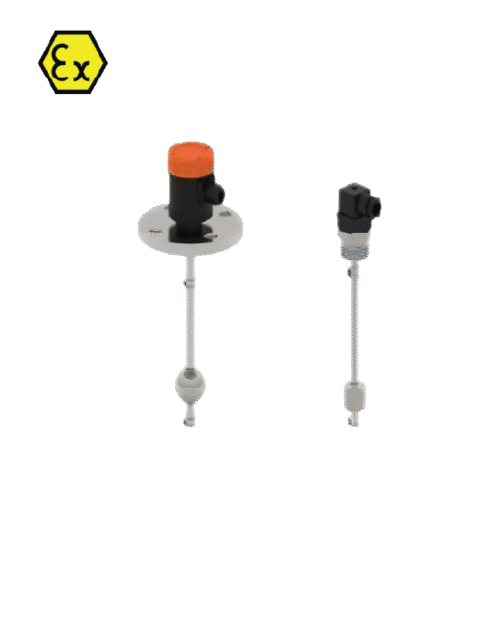

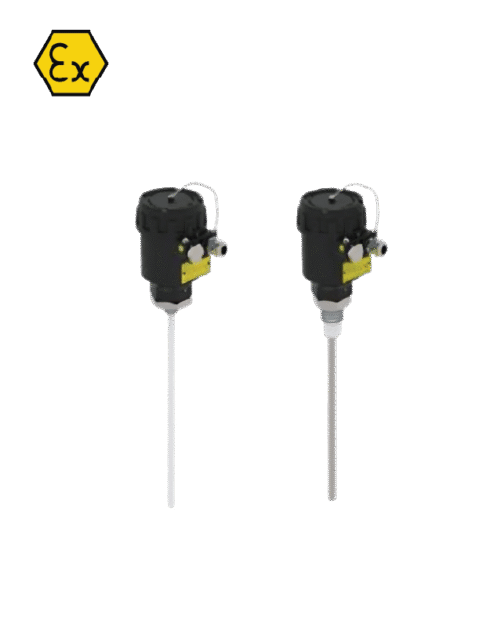

ECAPm / ECAPr / ECAPe | OEM Capacitive Level Sensor – Precision and Reliability for Industrial Level Measurement

The ECAP series—including ECAPm, ECAPr, and ECAPe—represents a new generation of high-performance OEM capacitive level sensor designed for accurate and reliable level measurement of liquids, solids, and semi-solid materials. Engineered for a wide range of industrial applications, these sensors combine advanced capacitive technology with rugged construction, ensuring consistent performance even under extreme conditions of pressure, temperature, and chemical exposure.

Whether used in chemical plants, food and beverage production, water treatment, or energy sectors, the ECAPm/ECAPr/ECAPe sensors provide dependable and maintenance-free operation, offering long service life and superior accuracy.

Operating Principle

The ECAPm, ECAPr, and ECAPe sensors function based on the capacitive measurement principle. Within the sensor, an internal electrode and the tank wall (or reference electrode) act as the two plates of a capacitor. The material to be measured—liquid, solid, or granular—serves as the dielectric medium.

As the level of the material changes, the dielectric constant varies, altering the capacitance value. This change is precisely measured by the internal electronics, which then generate a corresponding electrical signal. When the capacitance exceeds a set threshold, a relay or electronic output is activated, signaling that a specific level has been reached.

This non-contact and highly sensitive principle ensures accurate readings even for materials that are sticky, viscous, or prone to foam formation—conditions that often cause mechanical sensors to fail.

Electrical Characteristics and Performance

The ECAP series sensors are designed for high stability and precision in electrically noisy industrial environments. Operating within a 10 to 30 VDC supply range (maximum 35 VDC), they maintain low power consumption—typically less than 1 W, ensuring energy-efficient performance.

Depending on the model and process conditions, the resistance range can vary from 3 Ω to 1300 Ω, and the capacitance range from 1 pF to 3 nF. The sensors offer impressive accuracy from ±0.5% to ±5%, making them suitable for both high-precision and general-purpose level monitoring applications.

Each model features robust electronics designed to ensure stable signal output and minimal drift, even in environments with strong electromagnetic interference or rapid temperature fluctuations.

Construction and Materials

The mechanical design of the ECAP series reflects a perfect balance of strength, reliability, and adaptability. The wetted parts are made of 304 stainless steel, with an optional 316 stainless steel version available for highly corrosive or marine environments.

For the insulating and sensing components, premium-grade materials are used to ensure maximum compatibility and chemical resistance, including:

-

- PTFE (Teflon) and PFA for chemical and temperature stability.

- Delrin, Peek, or Ceramic for high-strength, high-temperature, and abrasive media.

- PVDF and Aluminum options for applications requiring lightweight and durable materials.

These material combinations make the ECAP sensors suitable for use in aggressive chemical environments, high-pressure vessels, and systems where hygiene and cleanliness are critical, such as food and pharmaceutical industries.

Pressure and Temperature Capabilities

The ECAPm/ECAPr/ECAPe sensors are designed to operate reliably under extreme process conditions. They can withstand pressures up to 150 bar, depending on the model configuration, and operate in a wide temperature range:

–30°C to +150°C under standard conditions

Up to 200°C with an additional cooling apparatus

Up to 230°C with Peek insulation for high-heat applications

For ambient conditions, the sensor remains fully functional from –20°C to +80°C, ensuring year-round performance in both indoor and outdoor installations. This makes the ECAP series suitable for industries like petrochemical processing, refrigeration, and energy production, where both extreme cold and heat may occur.

Installation and Mechanical Specifications

Designed for flexibility and ease of installation, the ECAP sensors feature multiple mounting and connection options. The standard process connection is 1/2″ BSP male thread, ensuring compatibility with most industrial tanks and vessels.

For electrical connections, users can choose between terminal connections, ISO 4400 standard sockets, or cable gland options, depending on their system requirements. The sensors are built to handle tightening torques of 10 Nm, 20 Nm, or 40 Nm, ensuring secure fitting without risk of mechanical stress.

Protection ratings of IP65 or IP67 guarantee excellent resistance to dust, water, and process contamination, making them suitable for washdown areas and outdoor installations.

The sensing length is customizable—ranging from 50 mm to 2000 mm—providing flexibility for both small and large tank applications.

Application Versatility

The ECAPm / ECAPr / ECAPe series is specifically engineered for versatility across multiple industries and materials, including:

-

- Conductive Liquids:

Water, acids, brine, and conductive solutions used in chemical, power, and wastewater industries. - Non-Conductive Liquids:

Oils, solvents, and refrigerants that require stable, non-intrusive level measurement. - Solid Particulate Materials:

Powders, grains, cement, and plastic granules in silos and hoppers. - Adhesive and Acidic/Basic Media:

Sticky or corrosive fluids like adhesives, glues, caustic soda, or acids, where PTFE, PFA, or Peek insulation ensures reliable operation.

- Conductive Liquids:

Each model—ECAPm, ECAPr, and ECAPe—is tailored to specific application needs:

-

- ECAPm: Compact and general-purpose design for standard liquid and solid materials.

- ECAPr: Reinforced and extended-range version for high-pressure or high-temperature environments.

- ECAPe: Economical version optimized for less demanding applications, providing cost-effective performance.

Key Advantages

- High Measurement Accuracy: Maintains ±0.5–5% precision across varying material types and dielectric constants.

- Robust Design: Withstands up to 150 bar pressure and 230°C temperature with durable stainless steel construction.

- Wide Media Compatibility: Works with conductive, non-conductive, and chemically aggressive materials.

- Maintenance-Free Operation: Solid-state sensing with no moving parts eliminates wear, sticking, and mechanical failure.

- Flexible Mounting & Connectivity: Available with multiple electrical and mechanical interfaces to suit any process configuration.

- High Protection Class: IP65/IP67 ensures protection against water jets, dust, and process splashes.

- Energy Efficient: Operates with maximum 1 W power consumption, contributing to overall system efficiency.

Information:

- Website: sensor-control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100

Reviews

There are no reviews yet.