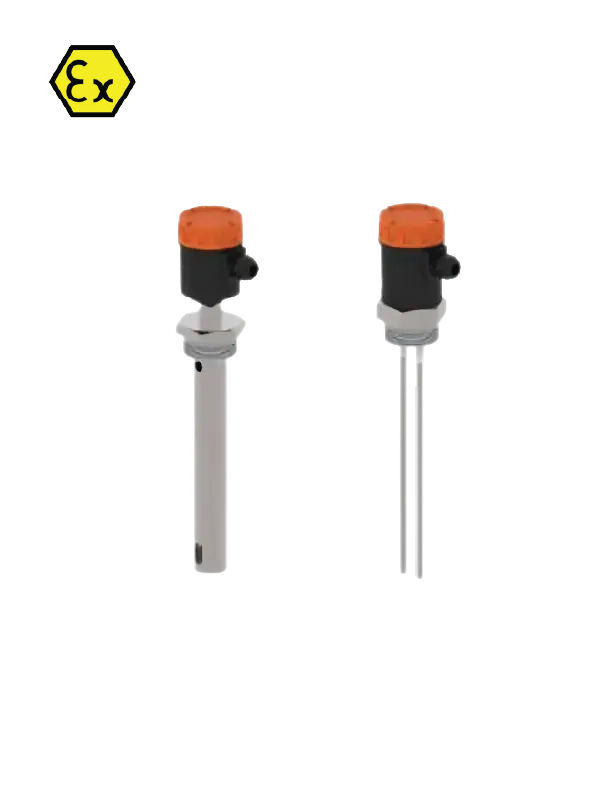

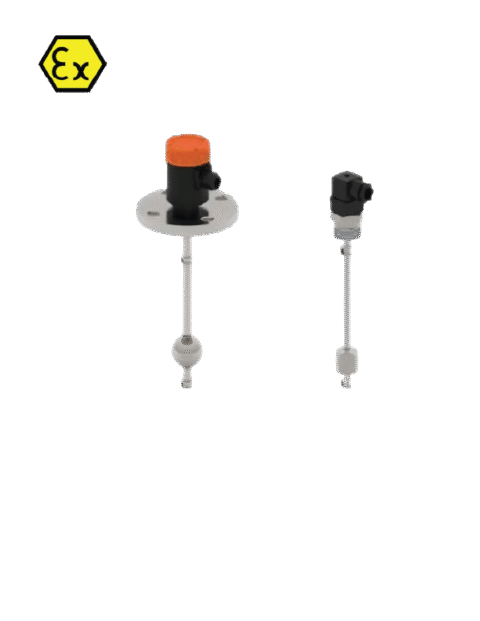

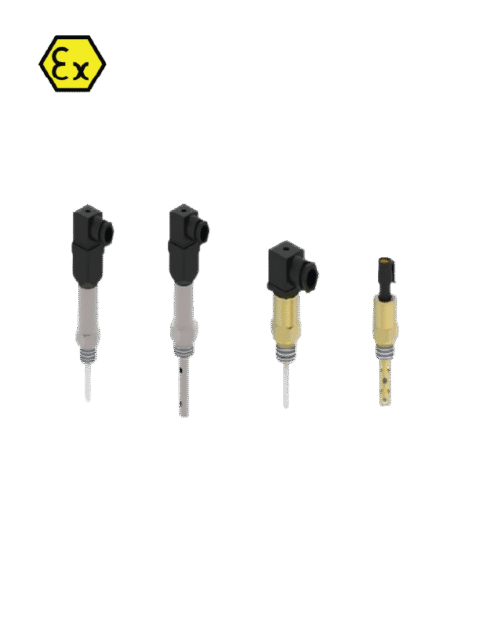

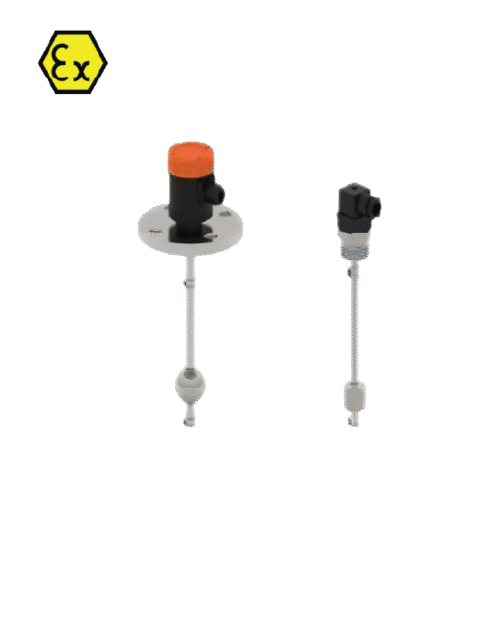

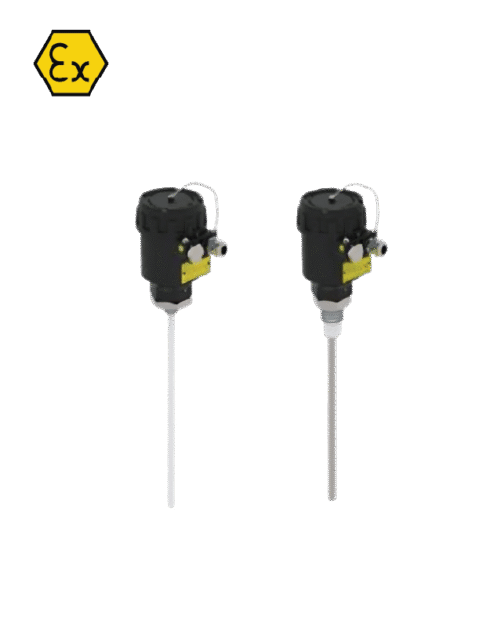

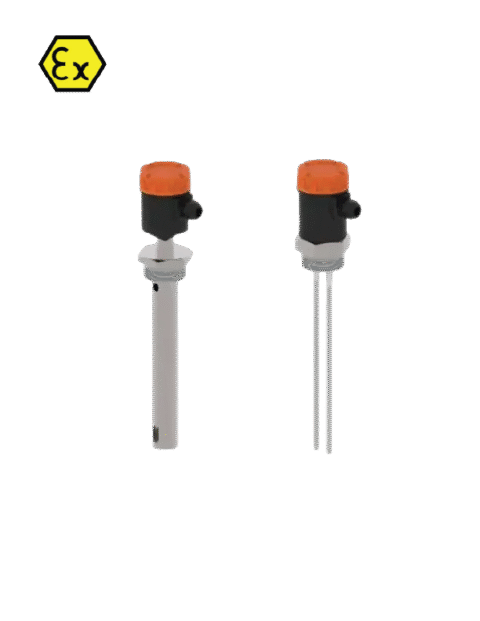

ECAS Capacitive Level Switch – Advanced Level Measurement for Liquids and Solids

The ECAS Capacitive Level Switches is a high-performance capacitive level sensor specially designed for precise and reliable level detection in a wide range of industrial applications. Built with robust engineering, it ensures accurate measurement of conductive and non-conductive liquids, granulated materials, and adhesive or chemically active substances, making it one of the most versatile level monitoring solutions available.

Working Principle

The ECAS Level Switch operates on the capacitive measurement principle. Inside the sensor, an electrode rod forms one plate of a capacitor, while the tank wall acts as the second plate. The material between these two components—whether liquid or solid—acts as a dielectric medium.

As the level of material changes, the capacitance value also changes. When this change exceeds a preset threshold, the system generates an electrical signal that triggers a contact output. This output can be connected to alarms, pumps, valves, or process control systems for automatic operation.

This smart capacitive sensing method enables non-contact, highly sensitive, and reliable level detection even in challenging industrial environments where conventional mechanical switches often fail.

Key Features

- Wide Application Range

ECAS sensors are suitable for liquids, solids, and powders—including both conductive and non-conductive materials. This makes them ideal for use in tanks, silos, and process vessels handling diverse substances such as water, oil, chemicals, and grains. - Designed for Harsh Conditions

The ECAS Level Switch is built to perform reliably under high temperature, high pressure, and corrosive environments. Refrigerated or special models are available for extreme process conditions, ensuring consistent accuracy and long service life. - User-Friendly Calibration

Users can easily adjust the trigger point and relay operation range directly on-site. This feature eliminates the need for factory recalibration and allows fine-tuning under actual process conditions, ensuring precise performance every time. - Flexible Mounting Options

The ECAS can be installed horizontally or vertically, making it adaptable to a wide variety of tank designs and process setups. Its compact and modular design ensures easy integration into existing systems. - No Moving Parts

The solid-state design ensures that there are no mechanical parts prone to wear, friction, or sticking. This results in minimal maintenance requirements and superior long-term reliability. - Insensitive to External Disturbances

The ECAS sensor is not affected by foam formation, liquid splashes, or vibrations, which often cause false readings in other level detection technologies. Its advanced signal processing ensures stable and accurate measurements. - High Pressure and Temperature Resistance

The rugged construction allows the sensor to operate safely under high pressure and temperature conditions, ensuring dependable performance in demanding industrial processes. - Compact and Modular Design

The modular architecture makes installation, replacement, and servicing quick and easy. Users benefit from a cost-effective and durable system that integrates smoothly with existing process equipment. - Reverse Assembly Operability

Even if the sensor is mounted in reverse, it maintains full operability, making it versatile and installation-friendly for technicians in the field.

Applications

The ECAS Level Switch is suitable for a wide range of industrial and commercial uses across multiple sectors:

Liquids

- Water and Wastewater Treatment: For monitoring levels in waste tanks, brine tanks, or process water systems.

- Oil & Petrochemical Industries: Ideal for oil tanks, CO₂ liquid tanks, glycol tanks, and other chemical storage systems.

- Food & Beverage Processing: Monitors liquid ingredients, dairy products, and cooling fluids in automated systems.

- Refrigeration & Cooling Systems: Used in cooling liquid tanks and refrigeration units for precise control of fluid levels.

- Chemical and Acidic Solutions: Resistant to corrosive liquids such as acids, bases, and solvents, ensuring long-term reliability.

Solids and Granulated Materials

- Agriculture & Food Industry: Measures levels of grain, flour, milk powder, sugar, and organic granules.

- Construction Materials: Detects cement, sand, or other construction materials in silos and hoppers.

- Plastics and Chemical Industries: Ideal for powdered resins, plastic granules, and other fine materials requiring accurate level detection.

Advantages at a Glance

- No Moving Parts: Ensures maintenance-free operation and eliminates mechanical failure risks.

- High Durability: Built to resist pressure, vibration, and temperature fluctuations.

- Insensitive to Foam & Splashing: Ensures consistent performance even with surface turbulence.

- Strong Mechanical Structure: Provides long-lasting performance under tough operating environments.

- Simple Zero & Span Adjustments: Easy calibration for user-defined detection points.

- Full-Length Measurement: The entire sensor length is active, ensuring reliable level detection at any point.

- Reverse Mounting Capability: Operates correctly even if mounted in reverse orientation.

- Cost-Effective & Reliable: Offers long service life with minimal maintenance costs.

Information:

- Website: sensor-control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100

Reviews

There are no reviews yet.