Float Switch For Water Tank – Precision, Durability & Intelligent Liquid Monitoring

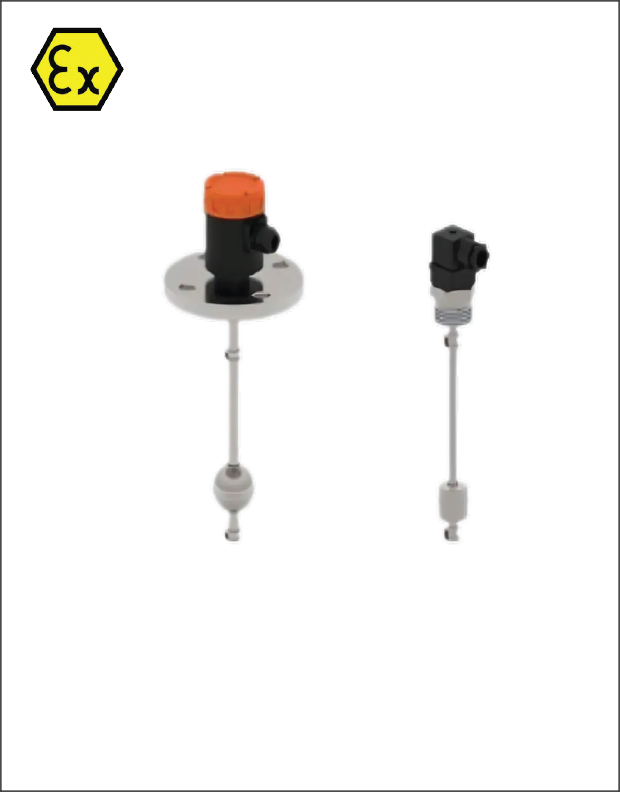

We are a top supplier of Magnetic Float Switch For Water Tank in the UAE, offering high-precision and durable level measurement solutions at the best price. Our sensors deliver accurate 4–20 mA output, customizable lengths, and robust stainless-steel construction suitable for water, oil, chemicals, and wastewater applications. With IP66/IP68 protection and temperature resistance up to 125°C, they perform reliably even in harsh industrial environments. We provide both standard and explosion-proof models for tanks, boilers, marine vessels, and hydraulic systems. With fast delivery, competitive pricing, and professional technical support, we ensure dependable and cost-effective level monitoring solutions across the UAE.

Reliable Level Measurement for Every Industrial Application

Accurate and stable liquid level measurement is essential across all industrial processes — from storage tanks and hydraulic reservoirs to boiler systems and wastewater management. The Magnetic Float Switch For Water Tank offers a high-precision, reliable, and cost-effective solution designed to perform consistently in even the most demanding environments.

Built on a proven magnetic float principle, this sensor delivers continuous, accurate level monitoring with exceptional long-term stability. Its robust stainless-steel construction, multiple configuration options, and compatibility with industry-standard signals make it suitable for a wide range of industrial, marine, and commercial applications.

Working Principle

The DX-ELS-TX Magnetic Float Switch For Water Tank operates using a simple yet highly reliable mechanism. A float containing a strong permanent magnet moves freely along a guide tube as the liquid level rises or falls inside the tank.

Inside the guide tube, a series of reed switches and precision resistors are aligned in a controlled configuration. When the magnetic float approaches a reed switch:

The switch changes its state (open/close)

The resistance value shifts

The system generates a continuous and proportional analog signal (typically 4–20 mA)

This output can be easily integrated with:

PLCs

Control panels

Relay/alarm circuits

SCADA or automation systems

As the placement density of reed switches increases, the resolution improves — enabling smooth, precise, and stable readings even in sensitive process environments.

Optional local display units allow operators to visually track the liquid level directly at the installation point without additional equipment.

Key Advantages

1. Versatile Material Selection

Available in both SS304 (standard) and SS316 (optional) for superior resistance to chemicals, corrosion, and temperature variations. Suitable for water, oil, fuel, chemicals, and process liquids.

2. High-Temperature Performance

Designed to operate reliably at temperatures up to 125°C, making it ideal for boilers, hot water tanks, and industrial heating systems.

3. Flexible Output Options

Standard 4–20 mA (2-wire) output for universal compatibility. Optional outputs include:

0–20 mA

0–10 V

Ohm output

3-wire configurations

4. Multiple Ignition & Connection Options

Choose terminals, cables, or socket connections to suit your installation requirements and maintenance preferences.

5. High Precision & Stability

Available resolutions of 15 mm, 10 mm, or 5 mm, providing extremely smooth and accurate analog signal output.

6. Customizable Lengths

Standard lengths up to 6000 mm (including thread). Easily customized for any tank height or application.

7. Rugged Environmental Protection

Rated IP66 / IP68, offering complete resistance to dust, moisture, and even full submersion — making it suitable for harsh and outdoor environments.

8. Fast Delivery & Technical Flexibility

Available in various configurations with quick delivery and tailored engineering support to match your exact application needs.

Applications

The Magnetic Float Level Sensor is ideal for universal liquid level measurement in:

Industrial Tanks

Reliable level monitoring for storage, process, and mixing tanks.

Boilers

Accurate water level monitoring for industrial and residential boiler systems.

Sewage & Wastewater Treatment

Stable performance in corrosive, contaminated, or variable liquid environments.

Marine Applications

Perfect for water, fuel, and ballast monitoring in yachts, ships, and offshore systems.

Hydraulic Systems

Monitors and maintains oil levels in hydraulic reservoirs, presses, and industrial machinery.

Storage & Utility Rooms

Level control for tanks in warehouses, industrial facilities, and commercial buildings.

Works flawlessly with clean water, fuel, oil, chemicals, and wastewater, regardless of the complexity of the environment.

Why Choose Our Magnetic Float Level Sensor?

High Accuracy & Repeatability

Ensures consistent and stable readings even with turbulence or continuous fluid motion.

Maintenance-Free Operation

Only one moving component — the float — ensuring minimal wear and extremely low maintenance requirements.

Industry-Standard Analog Output

Easily integrates with PLCs, DCS, control systems, alarms, and automation platforms.

Custom Engineering Solutions

Designed and manufactured to match specific tank heights, connection types, and electrical output requirements.

Industrial-Grade Durability

Made with high-quality stainless steel and sealed components for long operational life in harsh conditions.

Enhanced Safety & Reliability

Explosion-proof and corrosion-resistant configurations available for oil & gas, chemical, and marine applications.

A Perfect Fit for Modern Industrial Automation

As industries increasingly move toward smarter monitoring and automation, the Magnetic Float Level Sensor provides the ideal combination of durability, precision, and technological compatibility. Whether used as a standalone transmitter or integrated into a complex automated control system, it ensures:

Smooth process operation

Reduced downtime

Increased equipment lifespan

Improved safety and monitoring efficiency

The Magnetic Float Level Sensor is a long-lasting solution that enhances system performance and provides reliable protection against overflow, dry run, and operational failures.

Contact Information:

- Website: sensor-control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100