In sectors ranging from Oil and Gas to chemical manufacturing industry, ensuring safety is non-negotiable. When your operational landscape is potentially explosive , having equipment that thrives even in the most hazardous environment conditions becomes imperative.

Thankfully, a host of national and international standards have been devised to govern equipment functioning in such perilous environments. Among these, the ATEX directive, a pivotal regulatory framework of the European Union, takes center stage. In this exploration, we delve into the essence of the ATEX directive, its functions, the mandatory ATEX certification, and a comparative study with other vital standards that underpin workplace safety within explosive settings.

Table of Contents

- What Is the ATEX Directive?

- What Does ATEX Stand For?

- What Is the Meaning of ATEX?

- Where Is ATEX Applicable?

- What Is an ATEX Zone?

- Why Must You Have ATEX Certification?

- What Is the Difference Between ATEX and IECEx Certifications?

1. What Is the ATEX Directive?

In industries dealing with potentially hazardous materials, familiarity with the ATEX directive is paramount. Recognized globally as a fundamental benchmark, the European Union’s ATEX directive sets the gold standard for the safe utilization of equipment within explosive atmospheres.

The ATEX directive is a European Union (EU) directive that deals with the regulation of equipment intended for use in potentially explosive atmospheres. “ATEX” is an abbreviation that stands for “Atmosphères Explosibles,” which is French for explosive atmospheres. The directive is formally known as Directive 2014/34/EU.

This directive establishes a baseline of essential requirements aimed at bolstering the safety and well-being of workers potentially exposed to explosive environments. Notably, this includes sectors such as offshore oil and gas operations.

Emerging in the aftermath of the catastrophic 2010 oil spill in the Gulf of Mexico, the ATEX mandate emerged as a response to the pressing need for enhanced safety measures in the handling of hazardous substances. The environmental disaster cast a spotlight on the perils associated with transporting such materials, triggering a concerted effort within the international community, particularly spearheaded by the European Union (EU), to establish stringent safety standards. These regulations aimed at fostering the secure engineering of transport items and guaranteeing safety during the transit of dangerous goods.

There are two main categories under the ATEX directive:

ATEX Directive 2014/34/EU (ATEX 114): This directive pertains to manufacturers of equipment used in potentially explosive atmospheres. It outlines the requirements for making products safe for such environments. Products covered under ATEX 114 are typically marked with the “CE” marking.

ATEX Directive 1999/92/EC (ATEX 137): This directive focuses on the safety of employees who work in potentially explosive atmospheres. It places responsibilities on employers to assess and mitigate the risks in their workplaces and protect employees from potential explosions.

Industries, particularly those involved in oil and gas, marines, petrochemicals, chemicals, mining industry rely heavily on the ATEX standards to provide unequivocal safety guidelines when handling and shipping perilous products worldwide. This directive serves as a steadfast guardian, ensuring that workers and environments remain shielded from the inherent risks posed by explosive atmospheres.

2. What Does ATEX Stand For?

ATEX originates from the French phrase “Atmosphères Explosibles,” encapsulating the very essence of its purpose – to ensure the safe use of equipment in environments potentially laden with explosive substances.

3. What Is the Meaning of ATEX?

ATEX, an abbreviation of “Atmosphères Explosibles,” serves as a critical regulatory framework that pertains to hazardous materials, particularly those prone to explosion. Its primary objective is to establish stringent requisites for companies engaged in the handling and transportation of these perilous substances. Moreover, ATEX places an unyielding emphasis on safeguarding employees from the potential risks associated with explosive events.

This directive holds immense significance for industries where explosive atmospheres are a potential hazard, necessitating robust safety measures to mitigate the inherent dangers. By designating materials as hazardous and imposing comprehensive requirements, ATEX fosters an environment where companies are compelled to prioritize the well-being of their workforce and the integrity of their operations.

4. Where Is ATEX Applicable?

ATEX finds its application in environments where the potential for explosions looms, arising from the presence of dust, vapors, or gases that possess the propensity to ignite or detonate and it’s defined in ATEX 1999 directive Article 7. Consequently, its scope encompasses a multitude of workplaces dealing with flammable or explosive substances. This inclusivity extends to factories employing flammable agents or generating combustible dust clouds. Furthermore, ATEX’s reach extends to diverse operations, such as chemical processing, paint spraying, flour production, and milk drying, where the risk of explosive atmospheres exists.

5. What Is an ATEX Zone?

The ATEX directive 1999 Annex I mandates that workplaces meticulously categorize zones where the potential for explosive atmospheres exists. This classification process hinges on factors like the likelihood and duration of an explosive atmosphere’s emergence, leading to the precise delineation of zone dimensions and locations.

For instance, zone classifications for hazards environment encompassing gas, vapor, and mist encompass the following:

-

Zone 0: Zone 0 denotes areas where the presence of hazardous gas, vapor, or mist capable of forming explosive atmospheres is frequent or persistent.

-

Zone 1: In Zone 1, the probability of explosive atmospheres containing hazardous gas, vapor, or mist is intermittent, occurring periodically but not extensively.

-

Zone 2: Zone 2 pertains to areas where explosive atmospheres containing hazardous gas, vapor, or mist are infrequent or transient.

Akin to these classifications, similar zones exist for other explosive hazards, such as dust and fibers:

-

Zone 20: This classification designates locations where the potential for explosive atmospheres involving a cloud of combustible dust is frequent or sustained.

-

Zone 21: In Zone 21, scenarios involving explosive atmospheres containing a combustible dust cloud are sporadic, arising periodically rather than extensively.

-

Zone 22: Zone 22 encompasses areas where explosive atmospheres involving a combustible dust cloud are rare, emerging for brief durations.

By meticulously segmenting hazardous areas into these distinct zones, the ATEX directive empowers industries to foster a safer work environment while navigating potentially explosive conditions.

6. Why Must You Have ATEX Certification?

ATEX certification is an essential safeguard, ensuring the suitability of equipment for use within potentially explosive workplaces. This certification typically involves an impartial third-party organization i.e. ExNBs Notified Bodies that conducts rigorous testing during the certification process. However, companies can self-certify certain minor equipment elements, such as technical drawings and user manuals.

Upon successful certification, equipment bears the distinguished “CE” marking, signifying compliance with European standards. Additionally, a distinctive “Ex” marking is affixed to denote official ATEX certification, solidifying its reliability in hazardous environments. This meticulous certification framework underscores the commitment to safety in workplaces dealing with explosive risks.

7. What Is the Difference Between ATEX and IECEx Certifications?

The IECEx System, standing for the International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres, plays a pivotal role in certifying equipment for global markets. In contrast to the ATEX certification, which primarily focuses on the European Union, IECEx certification is designed to facilitate international business by ensuring equipment and services’ suitability for safe operation in explosive environments on a global scale.

Derived from the IECEx framework, ATEX certification holds a specific regional scope tailored to the EU’s requirements. The IECEx System operates with several key objectives in mind:

-

Cost and Time Efficiency: Streamlining testing and certification procedures to reduce manufacturer costs and minimize the time-to-market for products.

-

Global Confidence: Enhancing international confidence in the evaluation of products and services by promoting adherence to rigorous safety standards.

-

Centralized Database: Maintaining a centralized international database for certified equipment and services, facilitating easy access to relevant information.

-

Market Reputation: Elevating the international reputation of equipment and services through the recognition of IECEx certification.

However, ATEX and IECEx certifications exhibit notable distinctions:

1. Jurisdiction: IECEx certification is internationally recognized, while ATEX certification holds jurisdiction exclusively within the European Union. Nevertheless, numerous companies outside the EU voluntarily adhere to ATEX standards.

2. Standards: ATEX certification doesn’t strictly necessitate conformity to International Electrotechnical Commission (IEC) standards. Instead, it mandates compliance with its distinctive Essential Health and Safety Requirements (EHSRs). Practically, many companies align their practices with IEC standards to demonstrate EHSR compliance.

3. Certification: ATEX services are provided by notified bodies (ExNBs) specific to certain EU countries. They issue EU Type Examination Certifications. In contrast, the IECEx Management Committee oversees a unified international certification process. IECEx certification bodies ExCBs and testing labs globally issue universally recognized Certificates of Conformity.

Understanding the nuances between ATEX and IECEx certifications is essential for businesses aiming to ensure safety in explosive environments while navigating both regional and international markets.

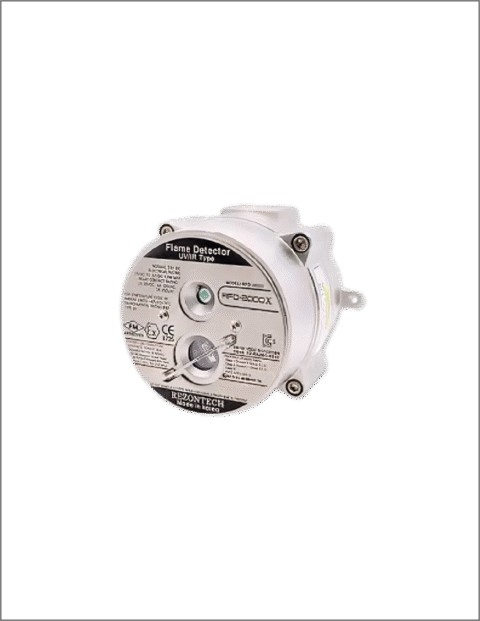

Explore a comprehensive range of ATEX-certified products, including lights, junction boxes, enclosures, air conditioners, control panels, and more. As a premier and reputable supplier, Sensor Control stands at the forefront of delivering top-notch explosion-proof solutions in the UAE. Contact us now to harness the power of safety-driven innovation for your hazardous environments.