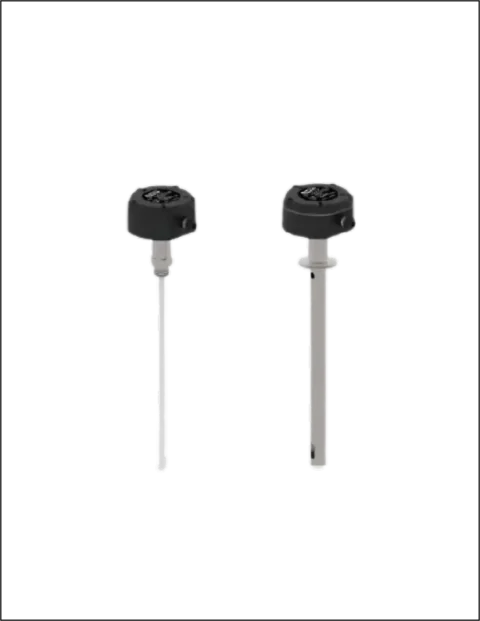

DX-ELS Float Type Level Switch – Precision Liquid Level Detection

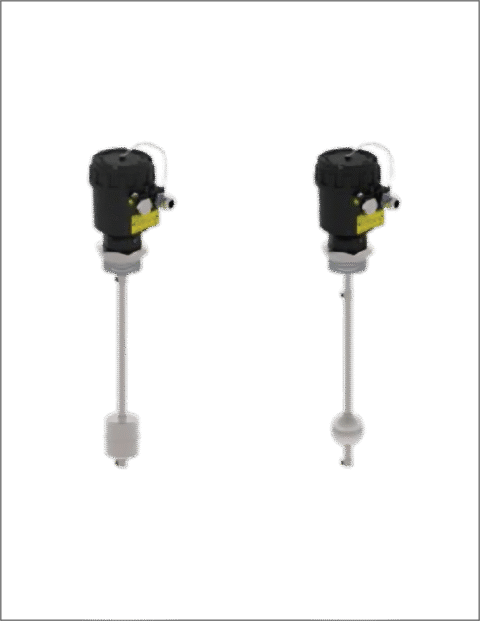

The DX-ELS Float Type Level Switch is a robust and reliable solution for liquid level monitoring across industrial, commercial, and process applications. Designed to provide accurate, repeatable, and maintenance-free operation, the DX-ELS series is widely used in tanks, vessels, and piping systems where precise point-level detection is critical.

Built with premium materials such as 304 or 316 stainless steel, with optional PU-coated floats, the DX-ELS ensures corrosion resistance, chemical compatibility, and long-term durability. Its rugged construction and versatile design allow installation in a wide range of liquids, from water and oils to acids, bases, and other chemical solutions.

Working Principle

The DX-ELS Float Level Switch operates on the magnetic reed switch principle. Each switch contains a float with a permanent magnet that moves along a vertical stem in response to liquid level changes. Inside the stem, one or more hermetically sealed reed contacts are positioned at pre-defined heights.

When the float rises or falls, the magnetic field activates the reed switches, either opening or closing the circuit. This electrical signal can be used to:

-

- Activate pumps

- Trigger alarms

- Control valves

- Interface with PLCs or DCS systems

Because the float operates without direct mechanical contact with the reed switches, the system ensures wear-free, frictionless, and highly reliable operation, even in turbulent or foamy liquids.

Construction and Materials

The DX-ELS is engineered with high-quality materials for demanding industrial conditions:

-

- Float Material: 316 stainless steel with optional PU coating for chemical resistance and buoyancy.

- Wetted Parts Material: Standard 304 stainless steel; optional 316 stainless steel for corrosive liquids.

- Pipe/Stem Material: 304 stainless steel standard; 316 stainless steel optional for aggressive environments.

- Float Type: S4A or S40A, selectable depending on liquid density and application requirements.

- Mechanical Connection: Standard 2″ BSP thread; optional customized threads available for specific tank fittings.

- Electrical Connection: Available via terminal box, pre-wired cable, or ISO 4400 socket for easy integration.

The sensor is designed for modular installation, allowing quick assembly, easy servicing, and flexible replacement without modifying existing piping or electrical systems.

Key Features

- Reliable Magnetic Operation:

Magnetic reed switching ensures contactless operation, eliminating mechanical wear and providing highly reliable level detection even in turbulent, foamy, or viscous liquids. - Maintenance-Free Design:

The non-contact mechanism and robust construction ensure long service life with minimal maintenance, making the DX-ELS suitable for continuous industrial operations. - Versatile Installation:

With a 2″ BSP standard connection and optional custom fittings, the sensor can be installed in tanks, process vessels, or piping systems of varying sizes. Multiple electrical connection options facilitate plug-and-play integration into industrial control systems. - High Temperature and Chemical Resistance:

Operating up to 125 °C, with 316 stainless steel and PU-coated float, the DX-ELS can handle aggressive, corrosive, or viscous liquids without degradation. - Flexible Configuration:

Available with single or multiple floats, variable stem lengths up to 2.5 meters, and additional contact points, making it ideal for single-point or multi-level detection applications. - Industrial Protection:

Rated IP66/IP68, the DX-ELS is resistant to dust, water ingress, and full immersion, ensuring reliable operation even in harsh industrial environments.

Applications

The DX-ELS Float Level Switch finds extensive application across industries:

-

- Water & Wastewater Treatment: Monitoring tank levels, wastewater, brine, and process water systems.

- Oil & Petrochemical: Detection of fuel, oil, lubricants, and chemical storage tanks.

- Chemical Industry: Compatible with acids, bases, and aggressive solvents for process control.

- Food & Beverage Processing: Suitable for liquid ingredients, oils, and process fluids in hygienic applications.

- HVAC & Refrigeration: Monitoring refrigerants and cooling liquids in industrial chillers and cooling systems.

- Marine & Shipping: Level control in bilge, ballast, and storage tanks under vibration and environmental stress.

- Power & Energy Sector: Boiler feedwater, lubrication, and process fluid monitoring.

Advantages

- Accurate & Repeatable Detection: Ensures precise switching for process automation and alarms.

- Non-Contact Magnetic Switching: Eliminates friction and mechanical wear for long-term reliability.

- Customizable Design: Stem lengths, float types, and multiple contacts to meet specific application requirements.

- Corrosion & Temperature Resistant: Handles up to 125 °C and aggressive chemicals without performance loss.

- Robust Protection: IP66/IP68 rated, suitable for outdoor and submerged applications.

- Flexible Electrical Outputs: Supports NO/NC configurations for easy integration with PLCs, relays, or control panels.

- Maintenance-Free: Reduces operational downtime and cost, ideal for continuous industrial use.

Information:

- Website: sensor-control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100