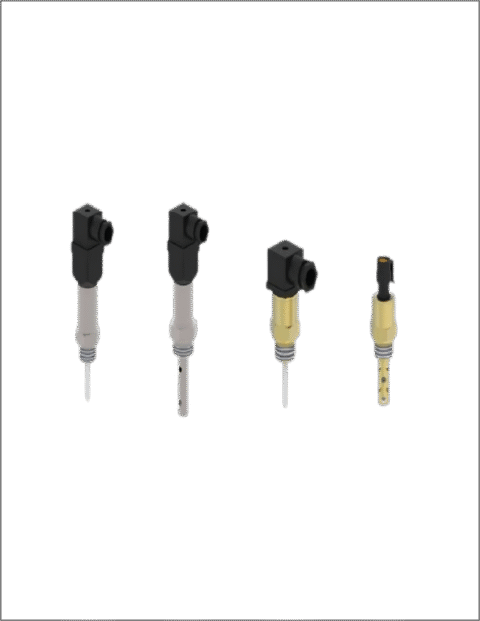

DX-ECAS Capacitive Level Switch – Precision Level Detection for Demanding Industrial Environments

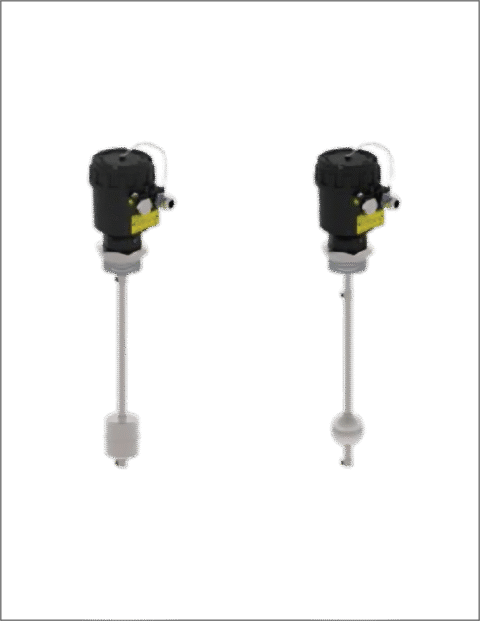

The DX-ECAS Capacitive Level Switch represents the next generation of advanced level measurement technology, engineered to deliver exceptional accuracy, durability, and versatility across a broad spectrum of industrial applications. Designed for both liquid and solid media, it ensures reliable level detection even in the most challenging process conditions, from high-pressure vessels to corrosive chemical tanks.

With its high-grade stainless steel construction, advanced sensor materials, and robust electronic components, the DX-ECAS series is the perfect solution for industries seeking stable and maintenance-free level monitoring in harsh and dynamic environments.

Operating Principle

The DX-ECAS operates on the capacitive measurement principle, where an electrode forms one plate of a capacitor, and the tank wall acts as the second plate. The material (liquid or solid) between them serves as the dielectric medium. As the material level changes, so does the capacitance value.

When this change surpasses a preset threshold, the built-in electronic circuit converts it into a switching signal that activates the relay output. This signal can be linked to alarms, pumps, valves, or process control systems, allowing for automated control and monitoring.

This contact-free and highly sensitive technology ensures dependable operation even under conditions that cause mechanical switches to fail, such as foam formation, viscous materials, or high vibrations.

Electrical Characteristics

The DX-ECAS Capacitive Level Switch operates at a 24 VDC power supply and incorporates a 1 NO/NC x 5 A / 250 VAC relay output, ensuring compatibility with a wide range of industrial control systems. The sensor provides reliable contact switching with high signal integrity and supports both normally open (NO) and normally closed (NC) configurations, giving users flexibility for various control applications.

The integrated LED indicators display both power and contact status, allowing real-time visual monitoring of operational conditions and simplifying on-site diagnostics. This feature is particularly valuable for technicians managing multiple sensors in large facilities.

The unit’s maximum voltage rating is 500 V, and power consumption remains below 1 W, reflecting efficient and safe operation in all environments.

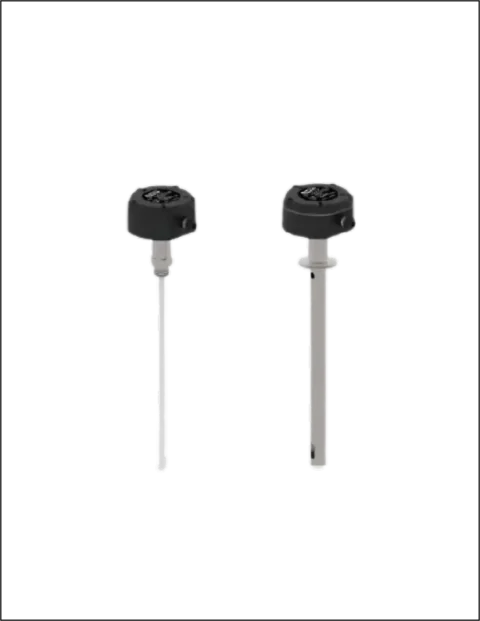

Mechanical Design and Materials

Every component of the DX-ECAS Level Switch is crafted with precision and durability in mind. The sensor body is made from 304 stainless steel as standard, with an optional 316 stainless steel version available for corrosive or marine applications.

The insulation materials—PTFE and PFA (with optional Peek or Ceramic)—offer exceptional chemical resistance and temperature stability. Peek and ceramic models are particularly suited for high-temperature or aggressive chemical processes, providing extended operational reliability up to 400°C.

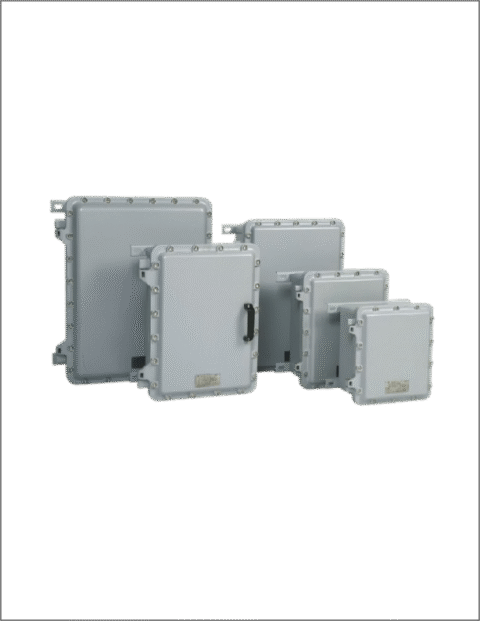

The housing is made from Aluminum Injection (AlSi12Fe) with a black anodized finish, ensuring strong resistance to mechanical impact, oxidation, and environmental stress. This makes the DX-ECAS ideal for outdoor and offshore installations where protection from moisture and corrosion is essential.

Pressure and Temperature Performance

The DX-ECAS sensor is designed to perform under extreme process pressures ranging from (-) 1 bar up to (+) 25 bar, depending on the specific model configuration. This broad range makes it suitable for applications such as pressurized vessels, hydraulic systems, or chemical reactors.

Temperature endurance is another highlight of the DX-ECAS series. Standard models operate from (-40°C to +150°C), while specialized versions can withstand:

-

- Up to 200°C with cooling apparatus

- Up to 230°C with Peek isolation

- Up to 400°C with ceramic insulation

These high-temperature capabilities make the DX-ECAS ideal for power plants, refineries, food processing, and other high-heat industrial environments.

For ambient operation, the sensor maintains stable performance within (-20°C to +60°C), making it suitable for both indoor and outdoor installations across varied climates.

Protection and Connection

Built to withstand harsh environmental conditions, the DX-ECAS features an IP66/IP68 protection rating, ensuring complete resistance to dust ingress and strong water jets, as well as temporary immersion. This level of protection guarantees safe and reliable performance in environments where moisture, condensation, or cleaning cycles are common.

The sensor uses terminal-type electrical connections, allowing secure and easy wiring during installation and maintenance. The robust terminal design prevents loosening due to vibration or thermal expansion, enhancing long-term reliability in dynamic systems.

Key Functional Advantages

- Non-contact, capacitive sensing suitable for liquids, powders, and granules.

- Maintenance-free solid-state design with no moving parts, ensuring long service life.

- Insensitive to foam, splash, and vibration, delivering consistent measurement under fluctuating conditions.

- Simple on-site calibration through adjustable zero and span controls, allowing users to fine-tune detection points as needed.

- Reverse mounting capability, meaning the device functions correctly even if installed upside down or at an angle.

- Compact and modular structure, facilitating quick replacement and integration with existing process systems.

- Low power consumption, contributing to energy-efficient plant operation.

Typical Applications

The DX-ECAS Capacitive Level Switch is widely used in industries requiring accurate level control and monitoring, including:

• Chemical and Petrochemical Plants – Ideal for monitoring corrosive liquids, solvents, and process chemicals stored in pressurized tanks.

• Food & Beverage Industry – Reliable detection of ingredients, powders, and viscous materials under hygienic conditions.

• Water & Wastewater Treatment – Used in storage tanks, sedimentation basins, and pumping systems for automatic level control.

• Energy & Power Sector – Monitors cooling fluids, condensate tanks, and lubrication systems under high temperature and vibration.

• Cement & Construction Industry – Ensures accurate detection of cement, sand, and aggregates in silos and hoppers.

• Plastics & Pharmaceuticals – Detects powders, resins, and granules where precision and cleanliness are critical.

Reliability and Maintenance

Thanks to its rugged mechanical structure and solid-state sensing technology, the DX-ECAS requires minimal maintenance. With no mechanical wear, friction, or clogging risk, downtime is greatly reduced. Periodic inspection and cleaning are typically all that’s needed to maintain full functionality.

The long service life and stable performance make it a cost-effective solution for industries aiming to improve operational efficiency while minimizing maintenance costs and process interruptions.

Information:

- Website: sensor-control.ae

- Email: sales@sensor-control.ae

- Phone: +971502447100